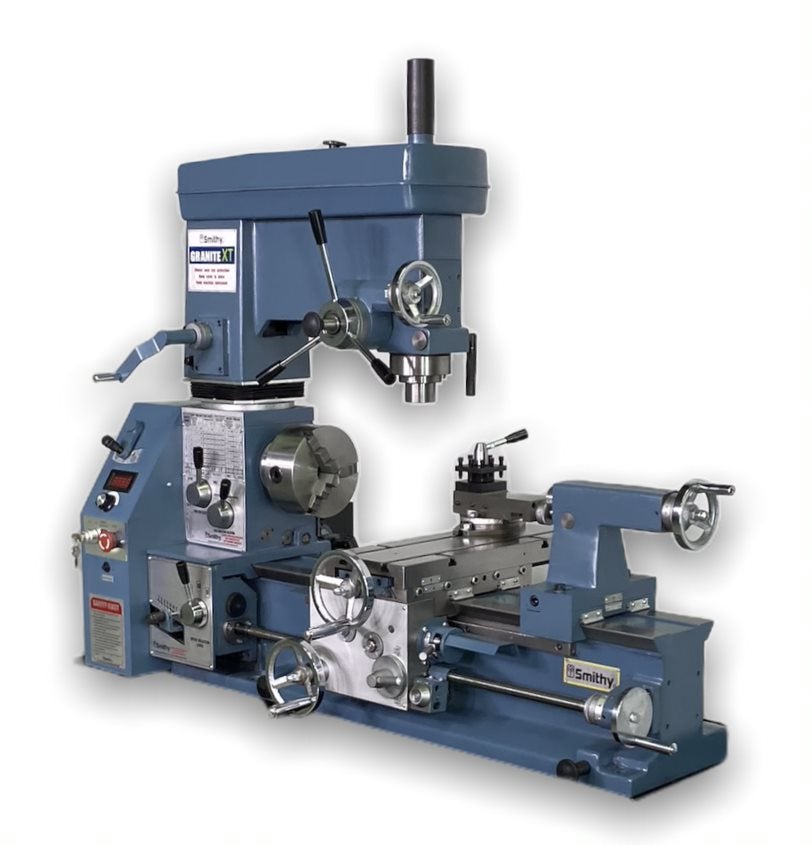

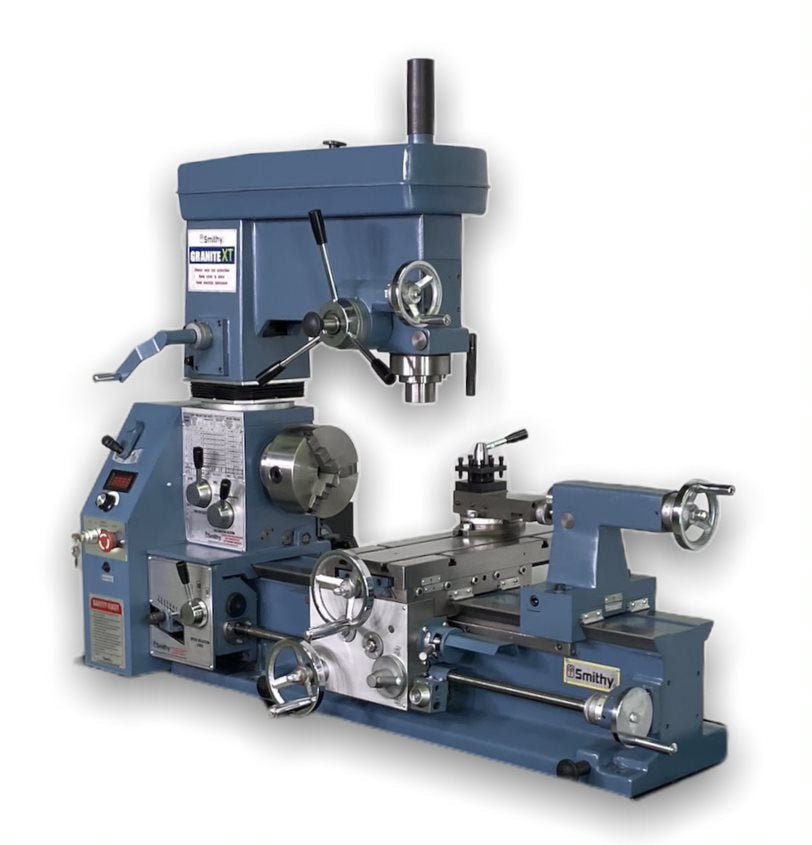

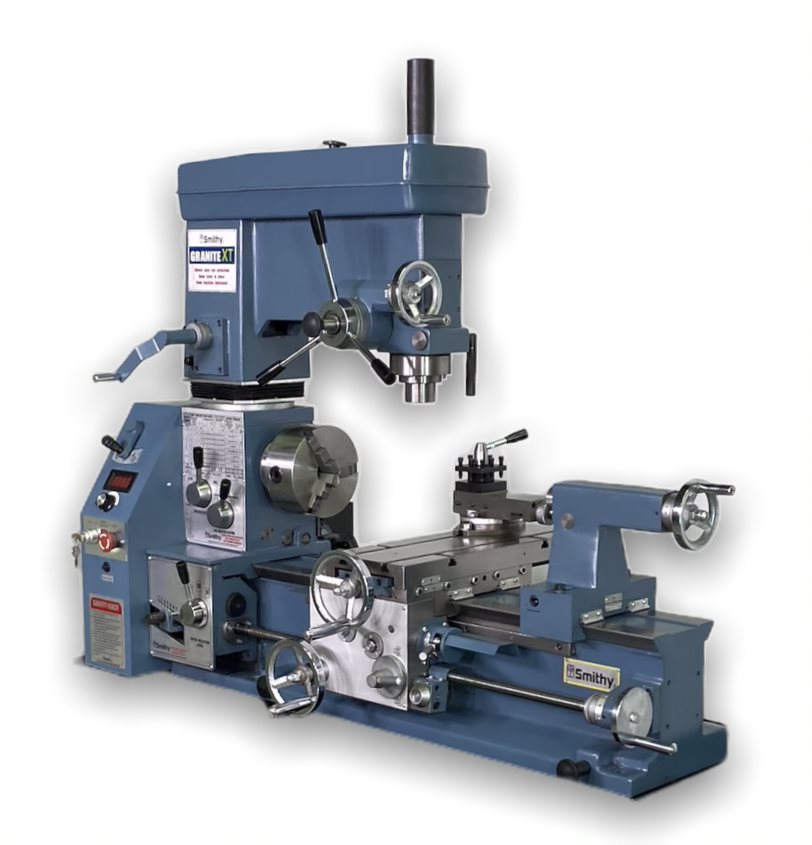

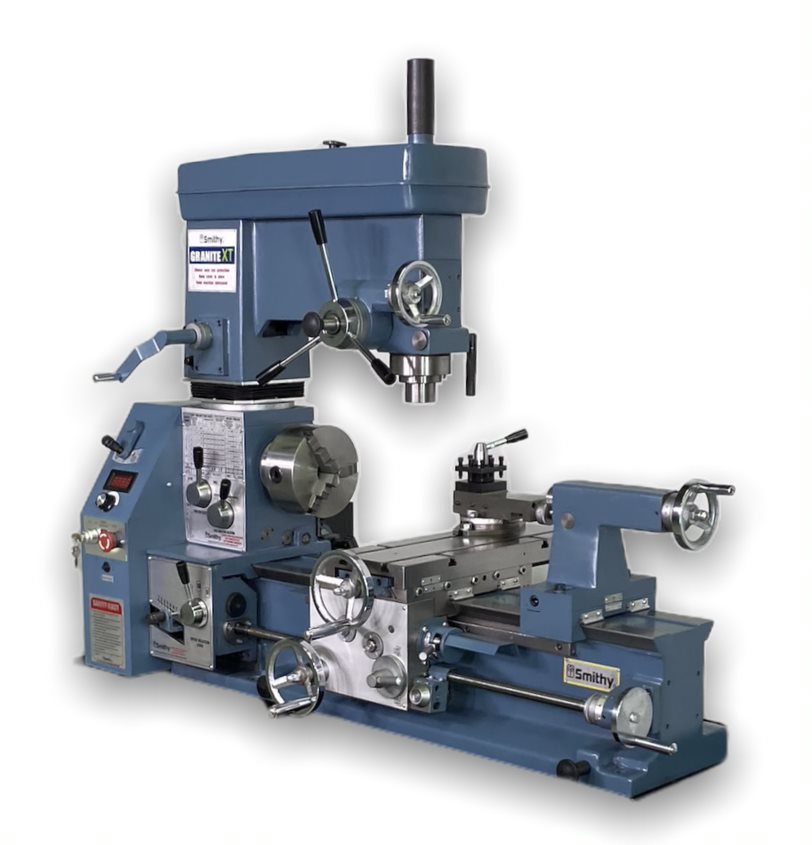

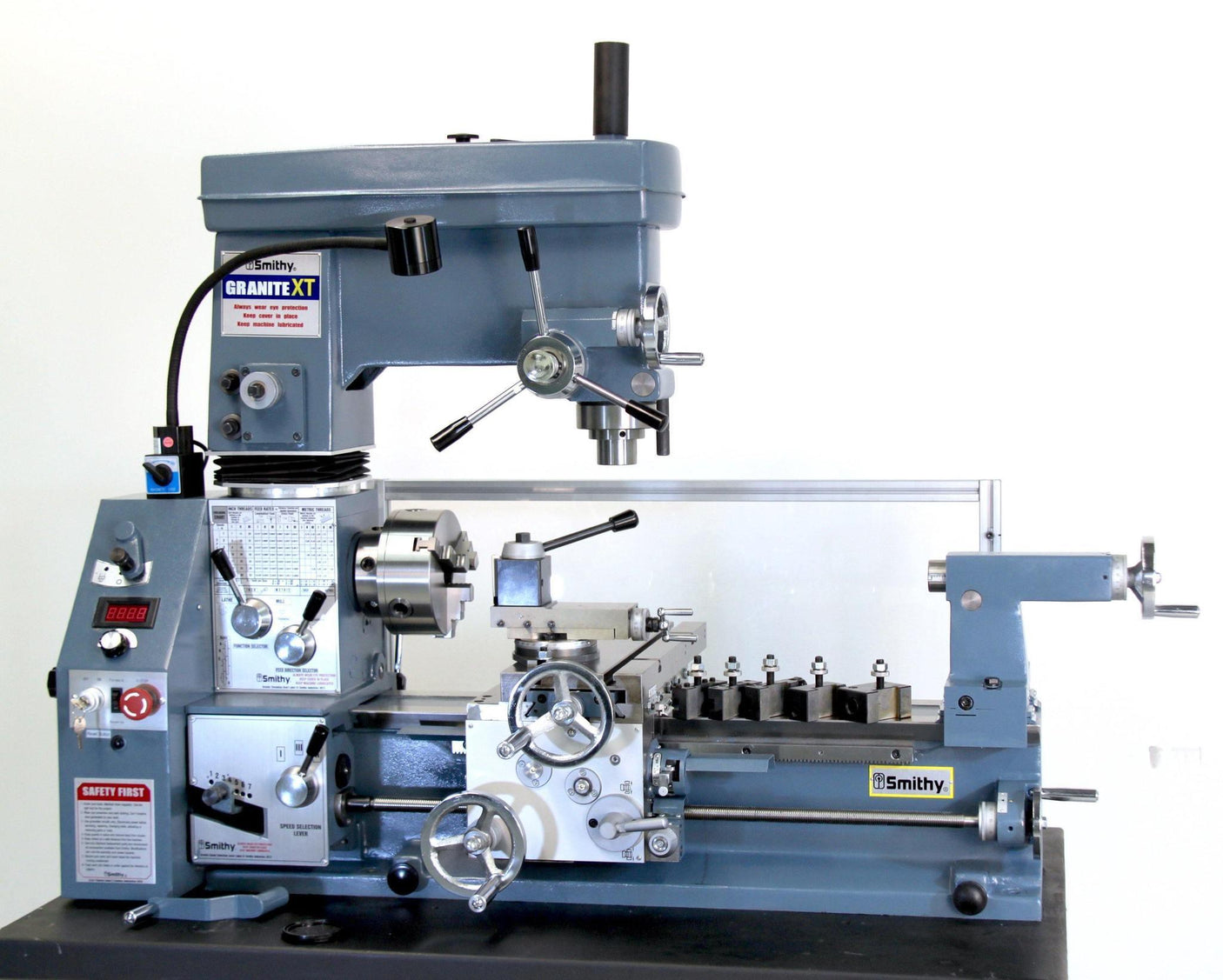

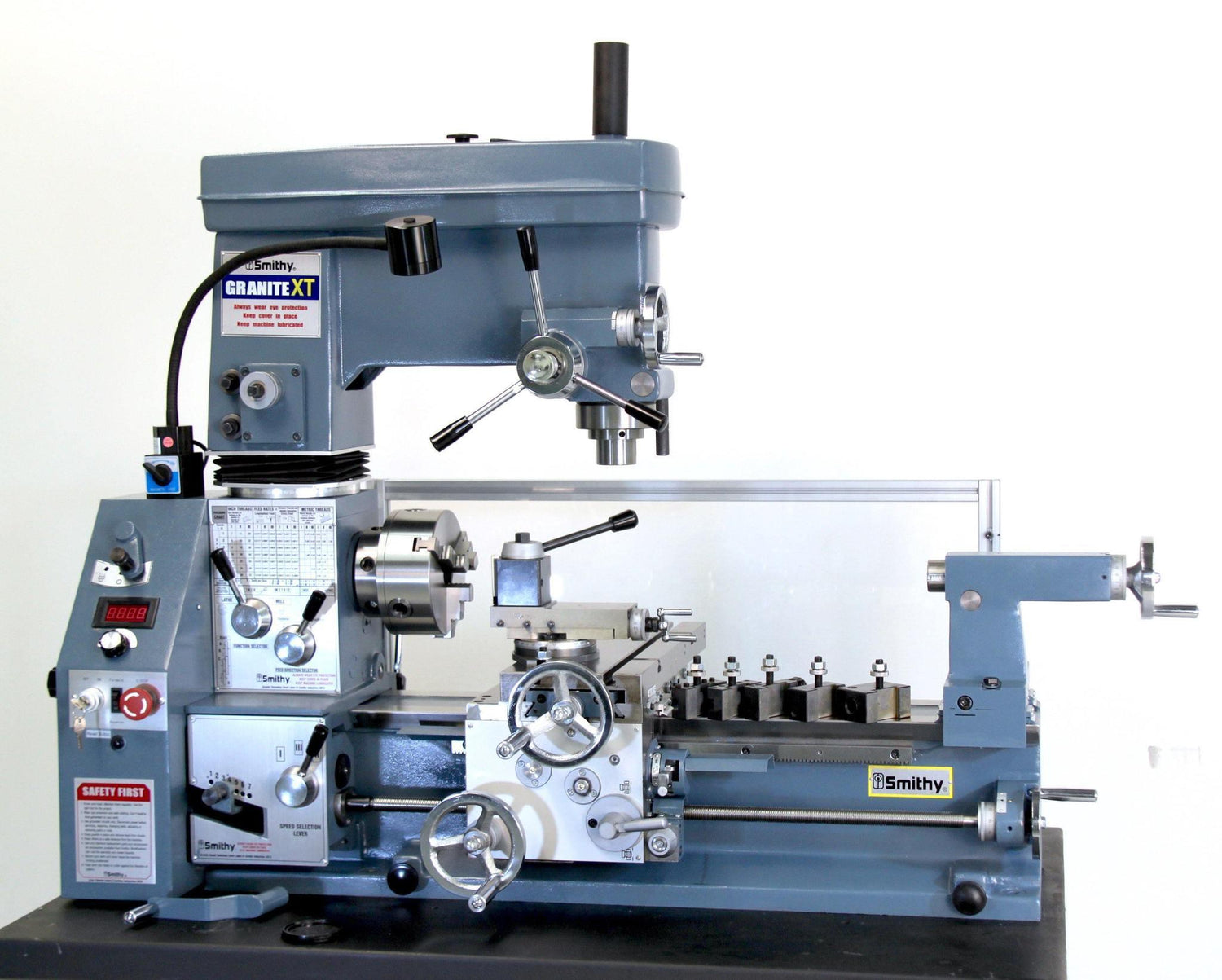

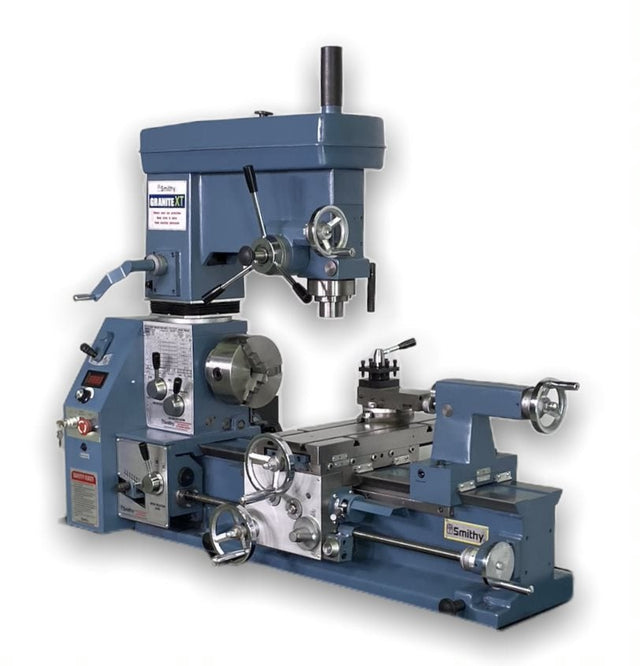

Granite XT 1324 110V Lathe Mill Combo

Granite XT 1324 110V Lathe Mill Combo - No Stand / No DRO / Basic Tool Pack is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

Granite - As Close As You'll Get to American Made

1) US Developed and Designed: By Smithy engineers in Ann Arbor, Michigan. Design ideas were based on machine user requests.

2) Higher precision than other combo tools: Granite components are machined to tighter specs - bearings are higher grade - basic design is higher precision.

3) Best Quality Production: Smithy engineers/technicians designed the Granite, and they oversee quality control during production and prior to shipment.

4) Superior Features: You can finish machining tasks -easier and faster- on a Granite machine.

Other 3-in-1 combo tools can't compare to the built-in quality and features of SMITHY tools.

Video Links

Smithy Training Videos - Learning to Machine on a Lathe Mill Combo

Years ago, Smithy produced a series of videos about learning to machine on a lathe mill combo machine. We hear often that these videos have been very helpful. This series is used in quite a few schools and tech training centers, literally throughout the world. Teachers like these videos because the concepts of machining are presented in a very logical way. Hopefully these videos will be helpful to you.

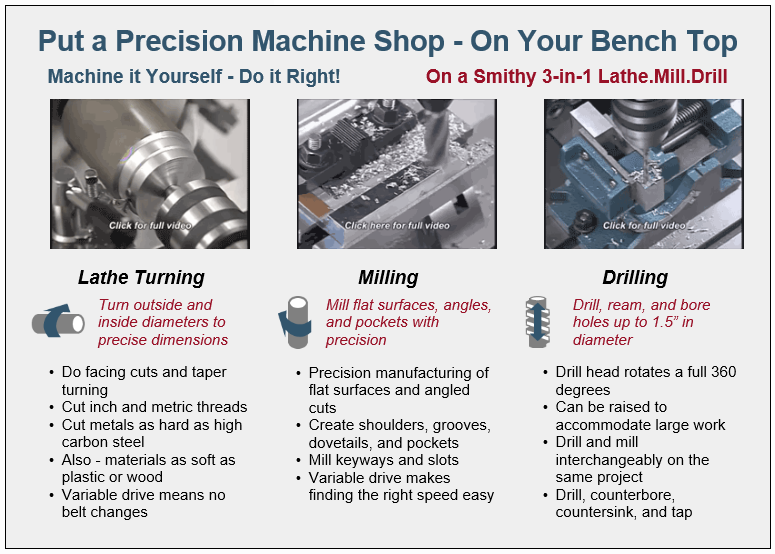

Best Practices - Lathe Turning

Introduction to standard metal late operations. An introduction to basic metal turning concepts is provided, along with basic instructions on lathe operation.

Workholding & Set up

Review of guidelines for installing a variety of work piece types and sizes on a metal lathe. This video covers turning between centers and proper mounting of a work piece in a lathe chuck. Proper use of lathe follow rests and steady rests is included.

Cutting Tool Selection

This video explains the selection and use of single point cutting tools on the lathe. Choosing the right cutting tool for a given operation is an important step when setting up a lathe. Selecting tool types and cutting speeds is also reviewed.

Facing Operations

This video demonstrates proper procedures and operator work process management for lathe turning and facing operations on a metal turning lathe. Reviews the various lathe turning operations that are typically used in a small shop setting.

Bench Top Milling & Drilling

Reviews the concepts of milling and drilling on a metal cutting mill/drill machine. Common practices in milling and drilling operations are presented. Tutorial on selecting best milling and drilling operations for a given task are provided.

Cutting Tool Selection

This video explains the selection and use of end mills and drill bits is covered. Choosing the right cutting tool for a given operation is an important step when setting up for a milling or drilling project. The foundation concept of selecting the best rotating cutting tool and cutting speed for a given project is also reviewed.

Workholding & Set-up

There are a wide variety of workholding tools that can be used to hold a work piece for milling or drilling operations. This video reviews the different concepts and practices in workholding for mill/drill operations. This video also offers some suggestions on workholding accessories to help you get started.

Basic Milling & Drilling Operations

This video starts by showing you machine controls used for milling and drilling operations on a small mill/drill machine. In this case, the Smithy Granite. The video also covers basic concepts and practices for effective metal milling and drilling on a bench top mill/drill machine.

Proper Machine Tool Maintenance

Proper maintenance of every machine tool is the key factor in that machine's ability to machine accurately and efficiently. Lubrication and maintenance are a big factor in assuring long life for every bench top lathe or mill/drill machine.

User Stories

Testimonials from Smithy's happiest customers

No Wait Time With My Smithy

"I have a granite 1324. I run a job shop outfit that does machining work for plastics manufacturing companies. My customers sometimes have orders with 2 or 3 day turn-around. I work in aluminum, plastic, and brass. What I enjoy most about Granite is the lathe work. It is really easy."

-Hai David Nguyen, L.K.B TX

More Convenient for Hobbyists

"I use my Smithy to make or modify parts for motorcycles and antique guns. I'm in this as a hobby. The Smithy probably has paid for itself but I haven't kept track. What is more important to me is the convenience of making my own parts, exactly as I need them when I need them."

-Kerry Klein, MI

Support Leads the Way

"I looked at other machining equipment but chose Smithy because of the quality, size, and availability of tech support. It's compact yet it does the work of larger units. It's a lot of machine that takes up a little space and it will pay for itself in the long run."

-Danny A. KY

Better Than a Grizzly

"After technical school, I did an apprenticeship in clock and watch repair and in tool and die making. I'm retired now and run a busy clock repair shop with my Smithy. I make parts for older clocks, cut clock gears, and make the cutters as well overhaul clock repair tools. I purchased a 9" x 19 bench lathe from Grizzly but returned it because of poor quality. I chose Smithy for its Sturdiness, its milling capabilities, and its compact size."

-William V-R., GA

No more down time

"Wendell and his business partner own a small textile factory. Last year, a German sewing machine clutch broke and production stopped. They weren't sure how long it would take to get a replacement part or if they could even find one. Putting their Smithy to work instead, they had the sewing machine back in production the same day."

-Wendell(Owner of Small Textile Company)

Granite XT 1324 110V Lathe Mill Combo

The Ultimate - For Business or Home

First choice for businesses and home shops when choosing the most powerful and efficient lathe mill combo that money can buy! Truly, the ultimate bench top machine shop!

New Granite XT 1324 Features:

- 13" Swing -40" Between Centers - Turn Longer Parts

- 2HP, 110 Volt Variable Drive - Cool and Efficient Running

- Standard R8 Spindle - Low cost, Easy to Use Tooling

- Quick-change Operation - Well Balanced Design

- Accurate to +/-0.001" - You will produce quality parts

Smithy Lathe Mill Combo

America’s Best Benchtop Machine Shop

Guaranteed to Pay its Own Way - From Production to Home Shop - America's #1 Lathe Mill Combo Machine

GRANITE: Quality, Precision, and Reliability Built-In

Premium Bench Top Machine Tool - America's #1 - for over 25 years

PRECISION: Compares to more expensive tools.

BALANCE: Easy change over for different operations.

FEATURES: Pro features help you work faster.

MASS: Heavy castings add more precision.

SPECS/FEATURES

-

Lathe Specifications

Bench milling machine for small shop features include:

- Gear-drive Spindle - for Power and Torque

- Built-In Z Axis Digital Read Out - Optimum accuracy

- Electric Powerfeed on X axis (Optional)

- 110/220V - You choose voltage for your shop

- Simple operations

- Accurate - Superior Gib Design

- Rigid dovetail ways provide stability and increased accuracy

Smithy Quality is Tops: Smithy designs and builds some of the best machines. We pay attention to details, all through the process. Smithy is well-known for it's after sales service and two year warranty. Each machine is inspected twice - before it leaves the factory and before it leaves our warehouse in Manchester, MI to head your way.

Financing Options

Consumer / Personal Financing

- 48-month financing plan

- 5.99% interest rate

- Promotional Financing Plan only when purchasing Smithy equipment

Commercial / Business Financing

- Soft-pull credit - doesn't affect credit score

- Flexible rates and payment plans

- Approval with low credut

Canada - Business Financing

- Soft-pull on credit - doesn't affect credit score

- Flexible rates and payment plans

- Approval with low credit

WHO BUYS THESE MILLS FROM SMITHY?

Businesses/Professional: Schools purchase quite a few. As so military organizations, R & D labs, etc. Small machine shop/production shops are frequent buyers.Garage/Home Shops: The machines are designed and built for professional parts production settings. Because of the quality features - and reasonable price - these rugged milling machines are also popular with home and garage shop machinists.

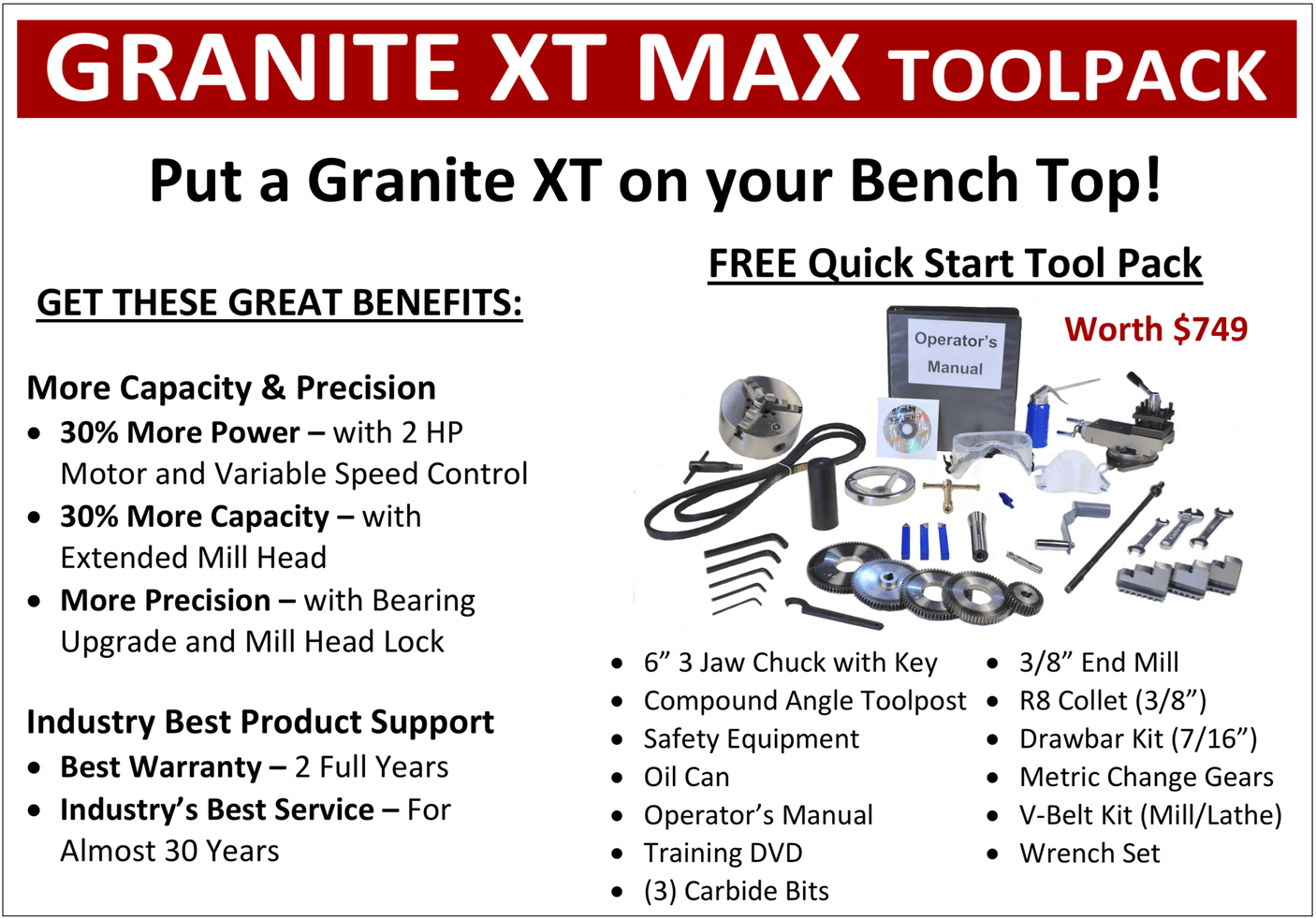

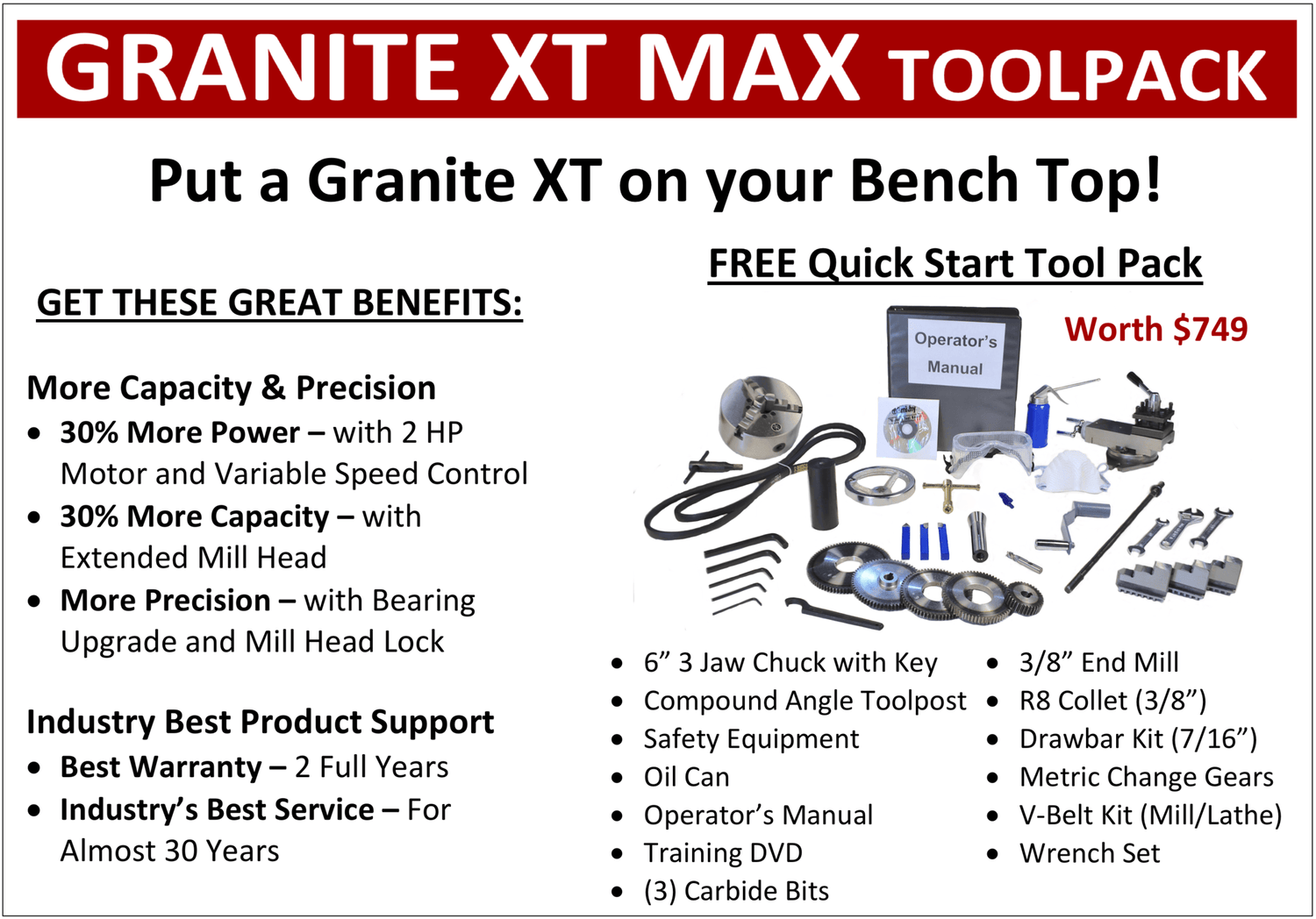

IS THE TOOL PACK HELPFUL?

The FREE tool pack is intended to proved a basic tool set-up to get you started when your machine arrives. It’s a balanced set of tooling, but you will likely need more tooling once you figure out specific projects you want to do.

WHAT DO YOU MEAN BY “INSPECTED TWICE?”

Each lathe is inspected by trained company employees at the factory - PLUS, a second complete inspection is performed at our warehouse in Ann Arbor, MI before it is sent to the customer.

WHY ARE THESE MILLS BETTER THAN OTHERS ON THE MARKET?

For a machine tool to be truly great it must have attention paid to every step of its development - design, production, quality control, testing, and after sales support. No other bench top lathe on the market, at this price, has the same level of quality commitment at every step as these MIDAS mills.

HOW LONG HAVE YOU BEEN SELLING THESE MILLS?

Over 30 years.

DO MANY LATHE BUYERS ALSO PURCHASE MILLING MACHINES?

Yes, the MI-1440 lathe matches well with the MI-409MZ milling machine - a machine shop combo that was built to last. Many customers buy this combination.

WHY SHOULD I BUY A MILLING MACHINE FROM SMITHY?

Rugged Design

Quality Built In

Inspected Twice

Best Service Support

The best bench top mill value - for over 30 years!

DO I NEED TO BE A MACHINIST TO USE THE MACHINE?

NO, many buyers of these machines don’t have the experience. What they have is the need to make a certain part or product. What you need is a commitment and curiosity. We have a set of machining training videos on our website. You can usually find classes at a local community college or vo-tech school. Get a machine and get going! You won’t be disappointed.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.