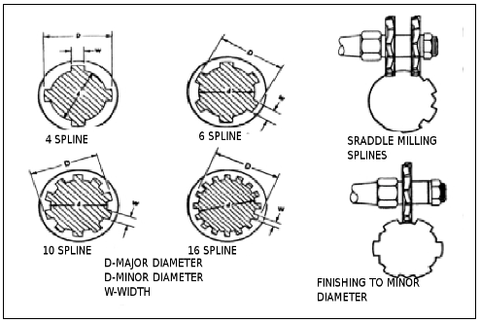

Spline shafts can be milled on the milling machine in a manner similar to the cutting of keyways.

The shaft to be splined is set up between centers in the indexing fixture.

Two side milling cutters are mounted to an arbor with a spacer and shims inserted between them. The spacer and shims are chosen to make space between the inner teeth of the cutters equal to the width of the spline to be cut (Table 8-8, Appendix A).

The arbor and cutters are mounted to the milling machine spindle. and the milling machine is adjusted so that the cutters are centered over the shaft.

The splines are cut by straddle milling each spline to the required depth (Table 8-8. Appendix A) and using the index head of the indexing fixture to rotate the workpiece the correct distance between each spline position.

After the splines are milled to the correct depth, mount a narrow plain milling cutter in the arbor and mill the spaces between the splines to the proper depth. It will be necessary to make several passes to cut the groove uniformly so that the spline fitting will not interfere with the grooves. A formed spline milling cutter, if available, can be used for this operation.

Figure 4-40.Milling spline shafts.

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

No products found