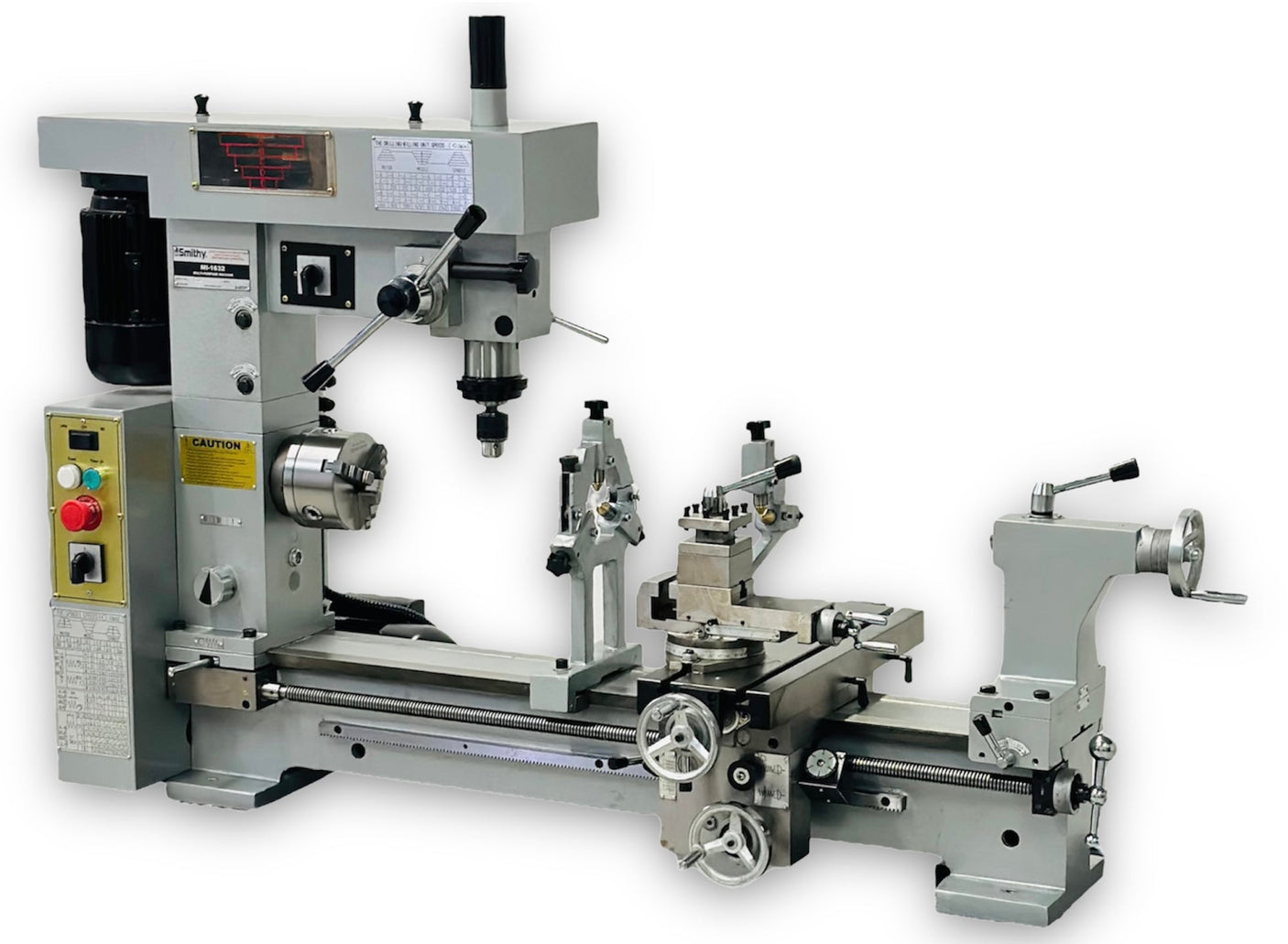

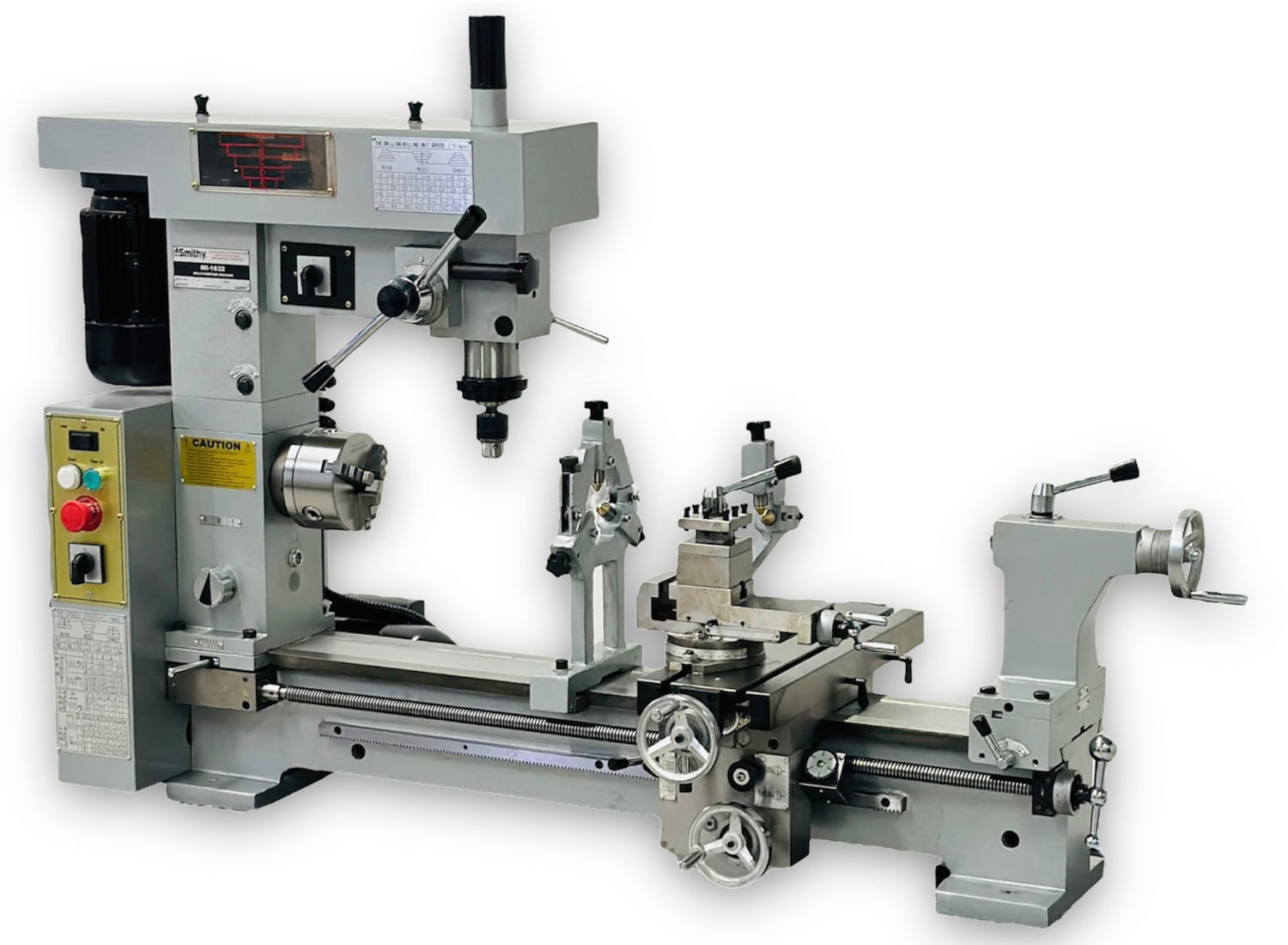

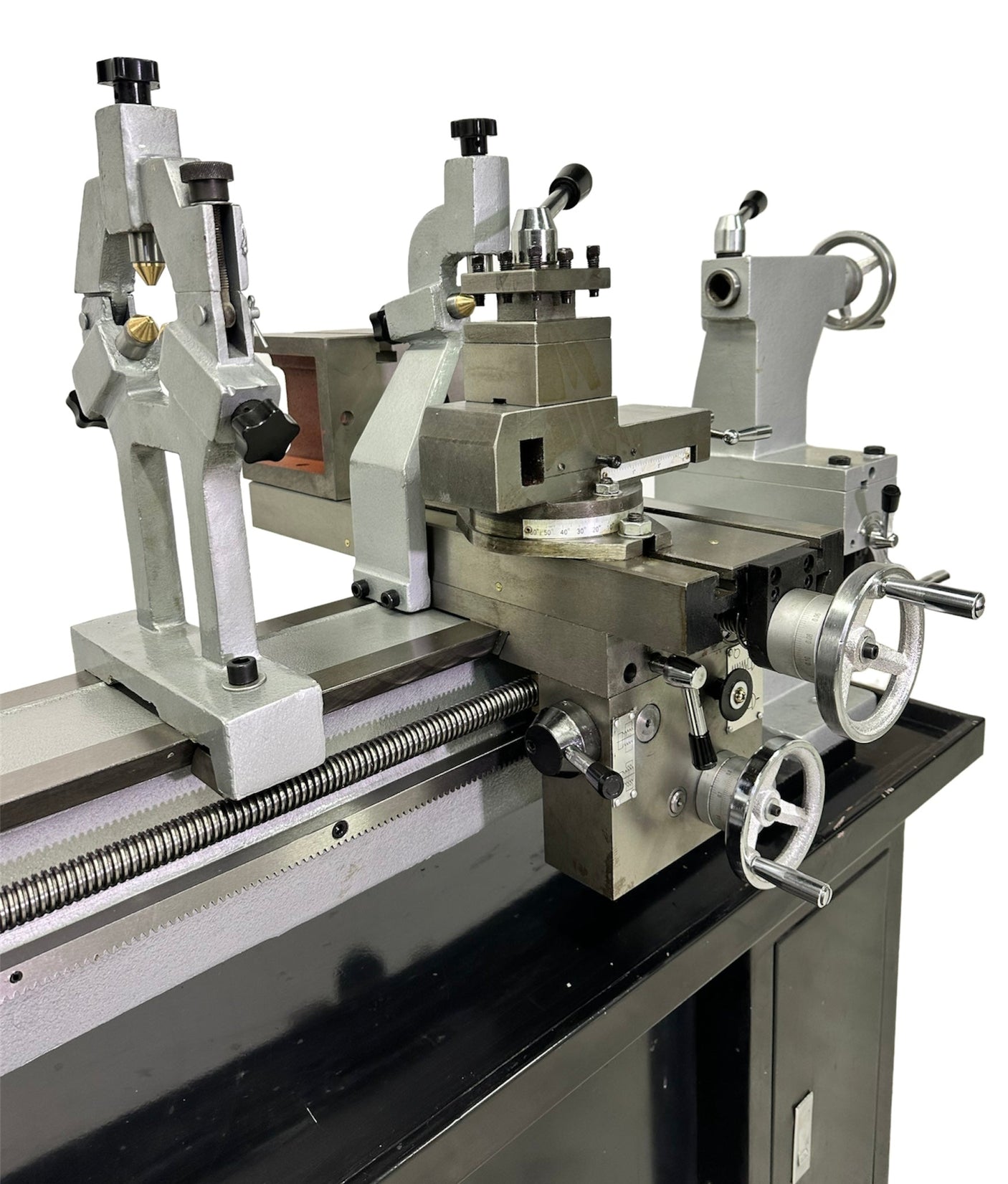

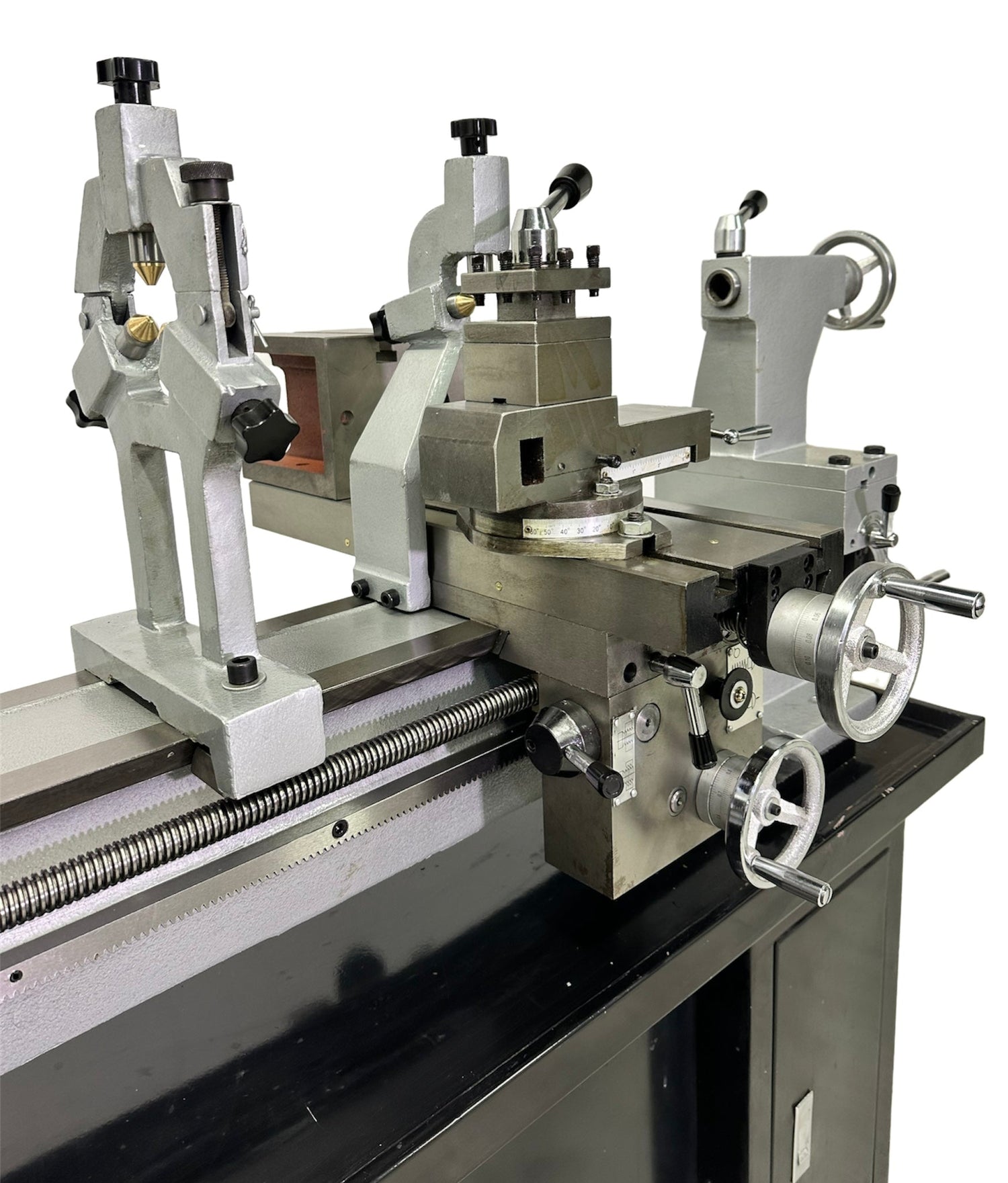

Mill-Turn 1620 Lathe Mill Combo

Mill-Turn 1620 Lathe Mill Combo is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

Video Links

Smithy Training Videos - Learning to Machine on a Lathe Mill Combo

Years ago, Smithy produced a series of videos about learning to machine on a lathe mill combo machine. We hear often that these videos have been very helpful. This series is used in quite a few schools and tech training centers, literally throughout the world. Teachers like these videos because the concepts of machining are presented in a very logical way. Hopefully these videos will be helpful to you.

Best Practices - Lathe Turning

Introduction to standard metal late operations. An introduction to basic metal turning concepts is provided, along with basic instructions on lathe operation.

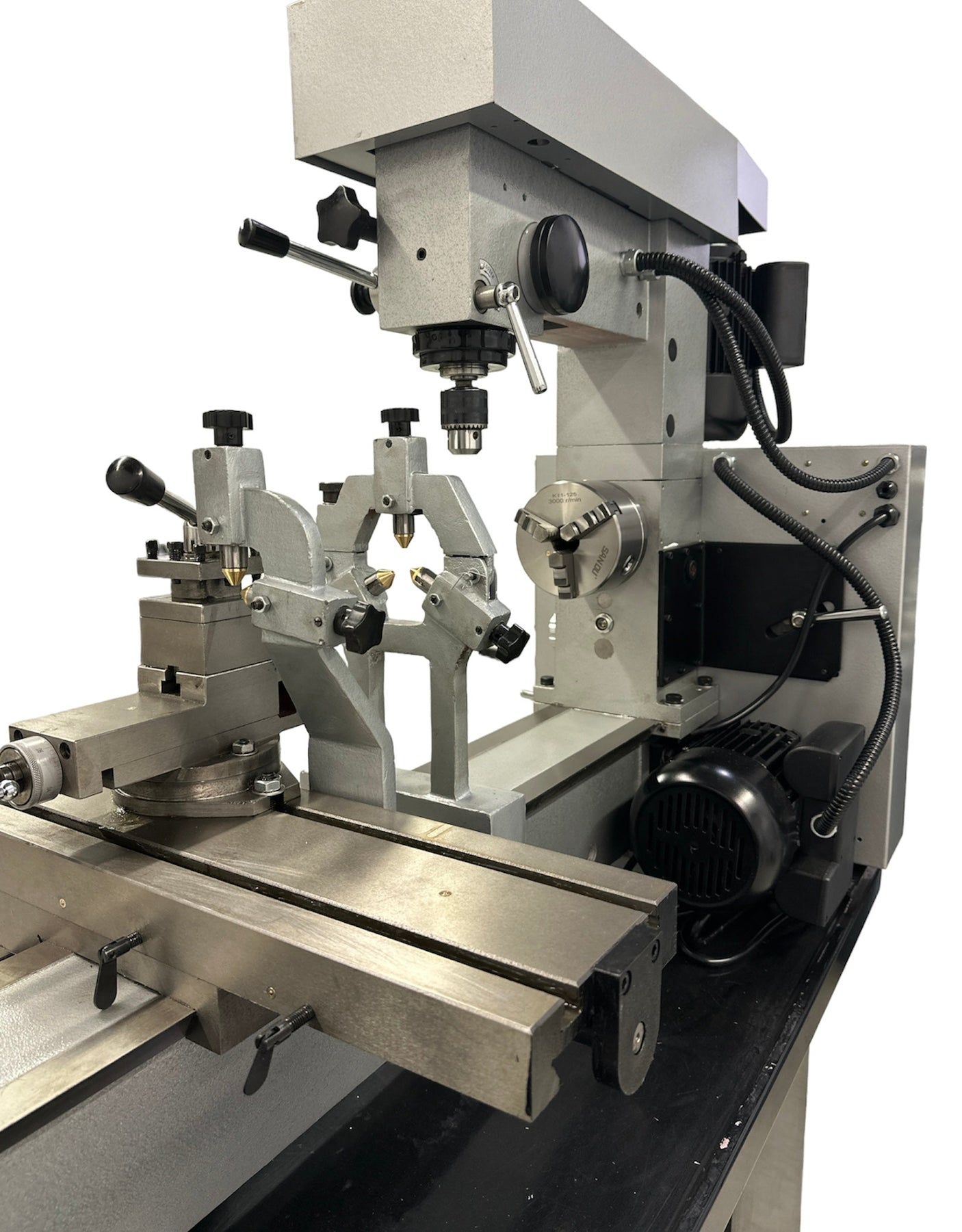

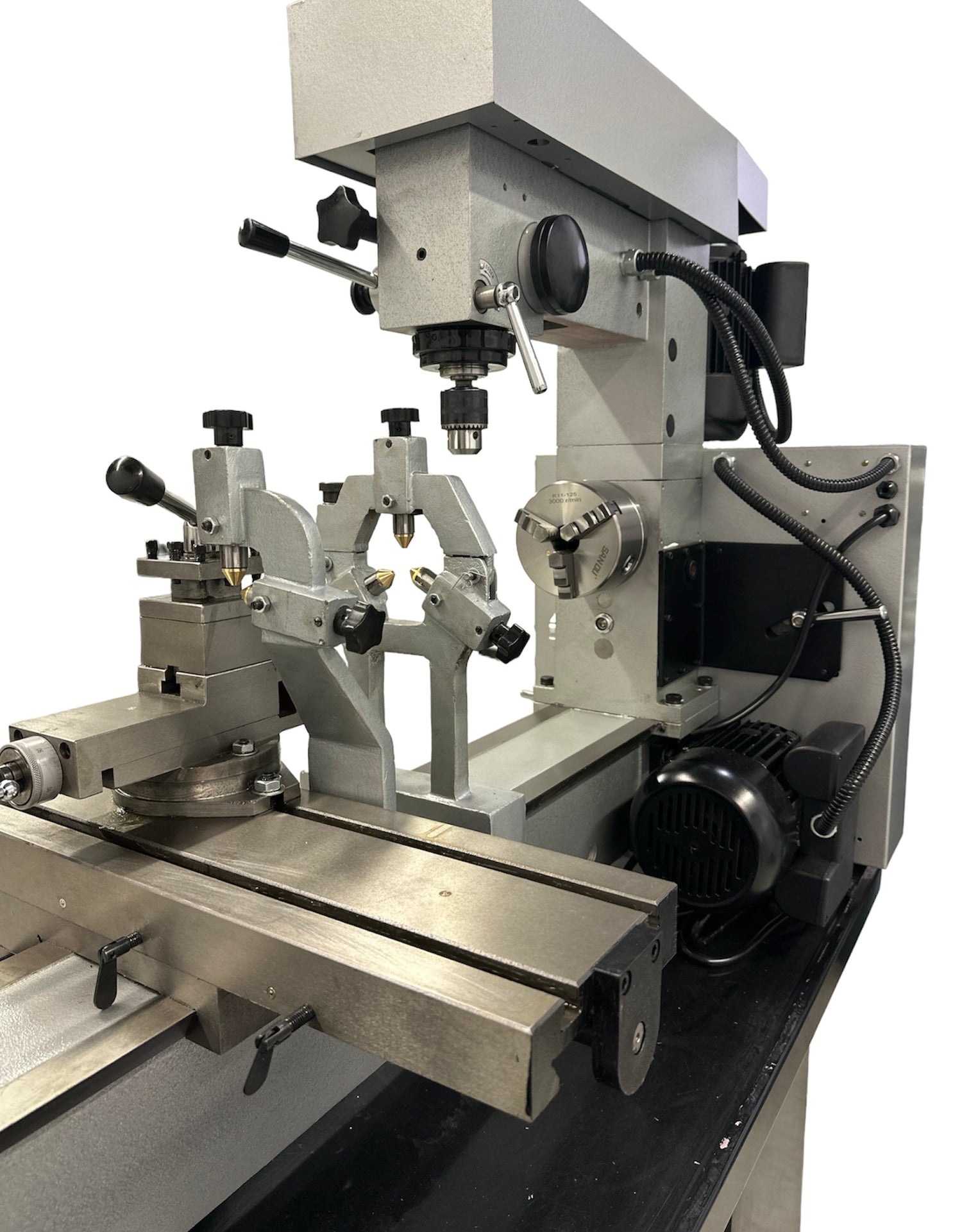

Workholding & Set up

Review of guidelines for installing a variety of work piece types and sizes on a metal lathe. This video covers turning between centers and proper mounting of a work piece in a lathe chuck. Proper use of lathe follow rests and steady rests is included.

Cutting Tool Selection

This video explains the selection and use of single point cutting tools on the lathe. Choosing the right cutting tool for a given operation is an important step when setting up a lathe. Selecting tool types and cutting speeds is also reviewed.

Facing Operations

This video demonstrates proper procedures and operator work process management for lathe turning and facing operations on a metal turning lathe. Reviews the various lathe turning operations that are typically used in a small shop setting.

Bench Top Milling & Drilling

Reviews the concepts of milling and drilling on a metal cutting mill/drill machine. Common practices in milling and drilling operations are presented. Tutorial on selecting best milling and drilling operations for a given task are provided.

Cutting Tool Selection

This video explains the selection and use of end mills and drill bits is covered. Choosing the right cutting tool for a given operation is an important step when setting up for a milling or drilling project. The foundation concept of selecting the best rotating cutting tool and cutting speed for a given project is also reviewed.

Workholding & Set-up

There are a wide variety of workholding tools that can be used to hold a work piece for milling or drilling operations. This video reviews the different concepts and practices in workholding for mill/drill operations. This video also offers some suggestions on workholding accessories to help you get started.

Basic Milling & Drilling Operations

This video starts by showing you machine controls used for milling and drilling operations on a small mill/drill machine. In this case, the Smithy Granite. The video also covers basic concepts and practices for effective metal milling and drilling on a bench top mill/drill machine.

Proper Machine Tool Maintenance

Proper maintenance of every machine tool is the key factor in that machine's ability to machine accurately and efficiently. Lubrication and maintenance are a big factor in assuring long life for every bench top lathe or mill/drill machine.

User Stories

Testimonials from Smithy's happiest customers

No Wait Time With My Smithy

"I have a granite 1324. I run a job shop outfit that does machining work for plastics manufacturing companies. My customers sometimes have orders with 2 or 3 day turn-around. I work in aluminum, plastic, and brass. What I enjoy most about Granite is the lathe work. It is really easy."

-Hai David Nguyen, L.K.B TX

More Convenient for Hobbyists

"I use my Smithy to make or modify parts for motorcycles and antique guns. I'm in this as a hobby. The Smithy probably has paid for itself but I haven't kept track. What is more important to me is the convenience of making my own parts, exactly as I need them when I need them."

-Kerry Klein, MI

Support Leads the Way

"I looked at other machining equipment but chose Smithy because of the quality, size, and availability of tech support. It's compact yet it does the work of larger units. It's a lot of machine that takes up a little space and it will pay for itself in the long run."

-Danny A. KY

Better Than a Grizzly

"After technical school, I did an apprenticeship in clock and watch repair and in tool and die making. I'm retired now and run a busy clock repair shop with my Smithy. I make parts for older clocks, cut clock gears, and make the cutters as well overhaul clock repair tools. I purchased a 9" x 19 bench lathe from Grizzly but returned it because of poor quality. I chose Smithy for its Sturdiness, its milling capabilities, and its compact size."

-William V-R., GA

No more down time

"Wendell and his business partner own a small textile factory. Last year, a German sewing machine clutch broke and production stopped. They weren't sure how long it would take to get a replacement part or if they could even find one. Putting their Smithy to work instead, they had the sewing machine back in production the same day."

-Wendell(Owner of Small Textile Company)

BIG FEATURES- SMALL PRICE

DO MORE than you thought Possible!

Smithy started the 3-in1 machine tool craze back in the mid-1980’s with the Midas. The Midas line remains as strong as ever: The all-in-one solution for individuals and companies that have smaller shops and budgets, do a moderate amount of machining, can forgo some “bells & whistles”… but demand Smithy quality and service all the way.

SPECIFICATIONS

|

Model Name |

MIDAS 1620 LTD |

|

Shipping Weight |

620 lbs |

|

Machine Weight |

500 lbs |

|

Crate Size |

47" x 23" x 45.5" |

|

Work Area Requirements |

36" x 72" |

|

Length |

48" |

|

Width |

25" |

|

Height |

40" |

|

Footprint |

18" x 60" |

|

T-Slot Size |

7/16" |

|

Powerfeed (X-Axis) |

Yes |

|

Powerfeed (Y-Axis) |

Yes |

|

Powerfeed (Z-Axis) |

No |

|

Threading Dial |

Yes |

|

Table Size |

5-5/16" x 18-5/8" |

ELECTRICAL SPECIFICATIONS

|

Model |

MIDAS 1620 LTD |

|

Ampherage |

8 (Lathe & Mill) |

|

Horsepower |

550 W (Lathe & Mill) |

|

Motor Type |

AC |

|

Phase |

Single |

|

Voltage |

110 A/C |

|

Frequency |

50/60 Hz |

LATHE SPECIFICATIONS

|

Model |

MIDAS 1620 LTD |

|

Distance Between Centers |

20" |

|

Dial Calibration Leadscrew |

.002" |

|

Dial Calibration Longfeed Rack |

.01" |

|

Dial Calibration Crossfeed |

.002" |

|

Dial Calibration Tailstock |

.001" |

|

Dial Calibration On Toolpost |

.002" |

|

Feed Rate (X-Axis) |

.0022-.014 |

|

Feed Rate (Y-Axis) |

.0011-.020 |

|

Headstock Taper |

MT4 |

|

Lathe Chuck Bore |

1.16 |

|

Lathe Chuck Diameter |

5” |

|

Lathe Chuck - Max. Diam/W/P |

5" |

|

Lathe Chuck - Min. Diam/W/P |

1/8" |

|

Lathe Chuck Mount |

Bolt-On |

|

Lathe Chuck Type |

3-Jaw Self Centering |

|

Spindle Bore |

1-1/16” |

|

Spindle Speeds |

Seven (160-1360 RPM) |

|

Spindle Accuracy TIR |

0.0016" |

|

Swing Over Bed |

16.5” |

|

Swing Over Worktable |

12" |

|

Tailstock Offset |

19/32" |

|

Tailstock Taper |

MT3 |

|

Tailstock Barrel Travel |

3" |

|

Threads (Metric) |

0.75 to 6 mm |

|

Threads (Inch) |

SAE 4-120 TPI |

|

Toolpost Travel |

3” |

|

Toolbit Size |

1/2" |

|

X-Axis Travel W/O Tailstock Or Threading Dial |

30.6” |

|

Y-Axis Travel |

7.75” |

MILL/DRILL SPECIFICATIONS

|

Model |

MIDAS 1620 LTD |

|

Dial Calibration Drill-Coarse Feed |

0.04" |

|

Dial Calibration Mill-Fine Feed |

0.04" |

|

Drawbars Size (Included) |

12mm, 3/8" |

|

Drill Chuck Size |

1/2" |

|

Drill Chuck Arbor |

MT3/JT33 |

|

Feed Rate (X-Axis) |

NA |

|

Feed Rate (Y-Axis) |

NA |

|

Head Rotation |

360° |

|

Head Travel Z-Axis |

0 |

|

Quill Diameter |

2-3/4" |

|

Quill Travel |

4-1/16" |

|

Spindle Center To Front Of Chuck |

6.5-1/16" |

|

Spindle Center To Lathe Spindle Flange |

9.5” |

|

Spindle Center To Column |

11.25” |

|

Spindle To Table Distance (Min.-Max.) |

8.75-11 7/8” |

|

Spindle Speeds |

16 (125-3000 RPM) |

|

Spindle Taper |

MT3 |

|

Tool Size Limit |

1" |

|

X-Axis Travel |

18.6 |

|

Y-Axis Travel |

7.75” |

FREQUENTLY ASKED QUESTIONS

WHO BUYS?

Home and garage shop machinists are still the most likely purchaser of a MIDAS machine; though there are thousands of units that are being used in a production setting. The MIDAS is not as automated and precise as the GRANITE line, but it is perfectly good and adequate for light duty applications. Buyers for GRANITE include schools, military, labs, and also home shop machinists.

I SEE TWO COMBO MACHINE DESIGNS OUT THERE ON THE MARKET. ONE IS THE "MILL HEAD MOUNTED ON THE LATHE SPINDLE" DESIGN, WHICH SMITHY DEVELOPED AND POPULARIZED. THE OTHER DESIGN HAS THE MILL HEAD MOUNTED ON THE BACKSIDE OF THE LATHE BED. IS ONE DESIGN BETTER THAN THE OTHER?

The combo machine with the mill head mounted behind the lathe bed has been around for over 60 years. It was developed by Emco-Meier and was sold by that company as the Maxi-Mat machine.

The design sold by Smithy was developed in the 1980's and quickly became popular because the Emco-Meier design had four disadvantages: 1) Much smaller milling capacity, 2) the mill can't be moved out of the way when you want to use the lathe (like you can with a Smithy combo), 3) the lathe turning cross feed capacity is limited because the mill head interfers with the travel of the work table, and 4) the size of the work table is limited because the mill head column is mounted so close to the lathe bed.

Among some combo machine operators the Emco-Meier design has the nickname "The Head Banger." This came about because an operator that is turning on the lathe can get focused on his project and forget about the mill head being in the way - the result being he bumps his head.

Overall, the Smithy Combo machine design offers more working capacity and higher efficiency and ease of use, compared to the traditional design.

IS THE TOOL PACK HELPFUL?

The FREE tool pack is intended to give you a basic tool set-up to get you started when you get the machine. It's a balanced set of tooling, but you will likely need more tooling once you figure out specific projects you want to do.

WHAT DO YOU MEAN BY "INSPECTED TWICE?"

Each lathe is inspected by trained company employees at the factory - PLUS, a second complete inspection is performed at our warehouse in Ann Arbor, MI before it is sent to the customer.

WHY ARE THESE LATHES BETTER THAN OTHERS ON THE MARKET?

For a machine tool to be truly great it must have attention paid to every step of its development - design, production, quality control, testing, and after sales support. No other bench top lathe on the market, at this price, has the level of quality committed to every step like these MIDAS lathes.

HOW LONG HAVE YOU BEEN SELLING THESE LATHES?

Almost 30 years.

ARE THERE MACHINE TOOL SELLERS OUT THERE NOW THAT TOOL BUYERS SHOULD BE AWARE OF?

The biggest change in the market recently is the increase in Chinese sellers coming into the market. They tend to sell cheap and buy knock-off products that don't have the quality of the traditional sellers. It is easy to start a website and throw a bunch of machines on it at low prices to see what sells. These companies tend to have poor service support on products that are poor quality from the start.

DO I NEED TO BE A MACHINIST TO USE THIS MACHINE?

NO, many buyers of these machines don't have experience - what they have is the need to make parts. Usually they already have something in mind they need to make. What is needed is a commitment to learn and curiosity. It will take time, but you will figure it out. We have a set of machining training videos on our website - you can usually find classes at a local community college or Vo-tech school. Get a machine and get going! You won't be disappointed.

WHAT SORT OF TOLERANCE CAN I EXPECT FROM THESE MACHINES?

The MIDAS specification is one thousandth of an inch production tolerance. The "TIR" (total indicated run-out) should not exceed .002" on any spindle assuming that you have followed proper setup procedures and have not exceeded the physical capacities of the machine or surpasses the safe feed/speed rates.

WHAT ARE THE MACHINE WEIGHTS AND DIMENSIONS? WILL THEY FIT IN A STANDARD 8' PICKUP TRUCK BED?

Yes, all Smithy combo machines fit into a standard 8' pickup truck bed. A disassembled machine stand willl also fit into the pickup bed, along with the machine.

ARE THE DIALS IN INCH OR METRIC?

Inch, the machine design and gearing is based on inch measurements. You can also cut metric threads with the 1220 LTD.

DOES THE MIDAS HAVE A HOLE THROUGH THE CENTER OF THE SPINDLE AND WHAT SIZE IS IT?

Yes, all MIDAS machines have a 1.03" spindle bore through the center of the spindle for passing stock through.

WHAT ARE THE POWER REQUIREMENTS FOR THE MACHINE?

MIDAS machines run on 110 volt power and plug into a standard household outlet. The motor draws 11 amps. We recommend using a dedicated 15 AMP breaker.

HOW MUCH SPACE DO I NEED TO ACCOMMODATE THIS MACHINE?

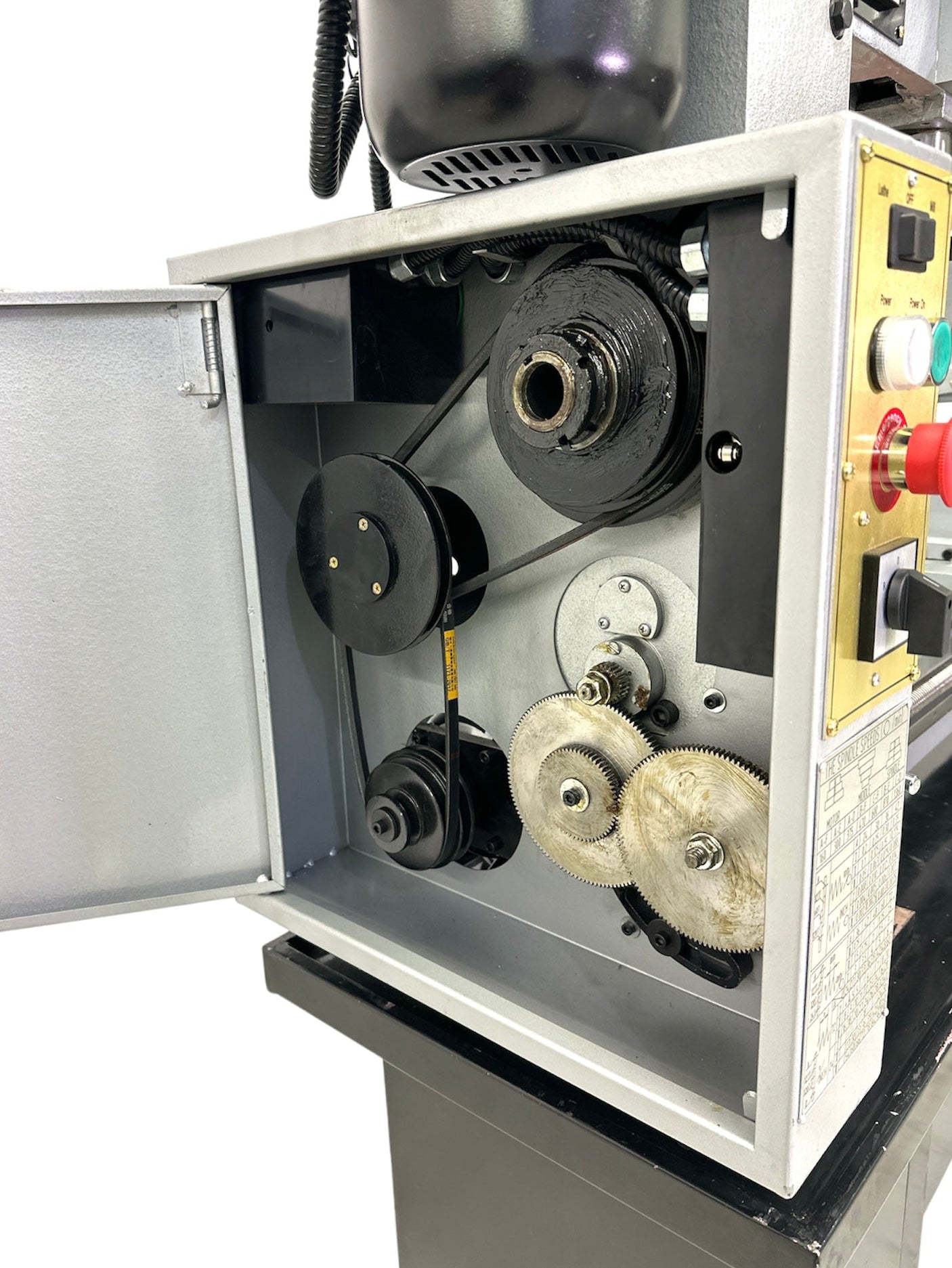

A MIDAS normally takes up the space required to store a bicycle. When planning for your MIDAS installation, be sure to account for movement around the machine and opening the pulley door on the left end.

HOW EASY IS IT TO CUT THREADS ON THE MIDAS MACHINE?

Cutting threads is accomplished by following the pitch chart to manually change gear to match the desired thread pitch. The threading dial helps you stay on track while cutting threads. Cutting inch threads is straight forward. Cutting metric threads can be accomplished.

MIDAS USES