|

Efficient sawing with sawing machines requires sharp saw blades in good condition. To prevent dulling and breakage of saw blades, proper speeds and feeds must be maintained. The speed of the saw blade for any specific operation depends upon the nature of the material being cut. POWER HACKSAWING Power hacksawing machines cut by drawing the hacksaw blade toward the motor end of the machine. At the completion of this movement called the draw stroke, the hacksaw blade is lifted slightly to clear the material being cut and moved an equal distance in the opposite direction. Mounting Workpieces Workpieces for metal cutting machines are not mounted to the machine, but are supported by the table of the machine and guided by one of the sawing machine attachments or by hand. |

Power Hacksaw Speeds. Since the cutting speed of hacksawing machines is measured in strokes per minuet, the length of the stroke is an important consideration. A longer stroke at a given speed will cut faster than a shorter stroke at the same speed. Thus. to obtain a proper cutting speed the length of the stroke must be specified. The length of the stroke of most power hacksaws is between 4 and 10 inches depending upon the size of the machine. On machines with an adjustable stroke, the wider the stock being cut, the shorter the stroke to prevent the blade holders from hitting the stock. With most power hacksaws, the stroke length is adjustable within 2 or 3 inches. and on some machines more than one speed can be selected. On single-speed hacksawing machines, the speed must be regulated by changing the stroke. |

|

If the stroke is doubled the machine will cut twice as fast, and if the stroke is decreased by one-half, the machine will cut half as fast. This proportion can be applied to any fraction to increase or decrease the cutting speed of the machine. The speeds given in the chart, Figure 7-16, bellow are for example only. The correct speeds for cutting various metals will depend on the type of machine you are using. In general the faster speeds are used for cutting soft materials and the slower speeds are used for cutting harder materials. If a recommended speed cannot be approximated either by changing the stroke or changing the speed, the feed can be decreased to prevent undue wear to the hacksaw blade. Power hacksaw machines having a mechanical feed can usually be regulated to feed the saw downward from 0.001 to 0.025 inch per stroke, depending upon the type and size of the material to be cut. On these machines, a device to stop the feed when hard spots are encountered is usually incorporated into the design. |

The feed of machines having gravity feed is regulated by the weight of the saw frame and any additional weights or springs that might be connected or attached to the frame to increase or decrease the downward force of the hacksaw blade. Maximum and minimum blade pressures obtainable are determined by the manufacturer of the hacksawing machine, and are specified as relatively light or heavy. The following general rules apply for selecting proper feeds for hacksawing machines:

|

Figure 7-16. Power hacksawing machine speed.

|

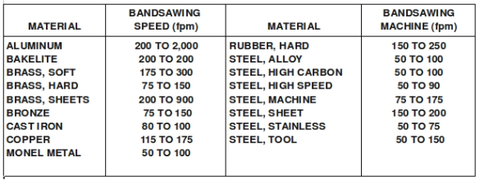

BANDSAWING The cutting speed of the bandsaw machine is the speed of the bands blade as it passes the table measured in feet per minute. The feed of the horizontal band saw machines downward pressure applied to the material being cut by the bands blade. The feed of vertical bandsawing machines is the pressure applied to the bands blade by the material being cut. Bandsawing Speeds Proper bandsaw speeds are important in conserving bands blades. Too great a speed for the material being cut will cause abnormally rapid blade wear, while too slow a speed will result in inefficient production. The chart of recommended speeds (Figure 7-17) are guidelines only. It shows the speeds for a given type of machine. The cutting speed always depends on the type of machine you are using and the manufactures' recommendations. All bandsawing machines have several cutting speeds. Since the diameter of the drive wheel of the bandsaw machine establishes a fixed ratio between the motor or transmission speed in RPM to the blade speed in FPM, it is not necessary to convert RPM into FPM as with most other machine tools. The speeds are identified in FPM on the sawing machine speed selector controls. Some machines have a speed indicator so a careful check of sawing speeds may be made when the machine is operating with or without a load. In general the following principles apply to speeds of bandsaw blades:

|

Horizontal Bandsawing Machine Feeds Feed of horizontal bandsaw machines is controlled by adjusting the pressure applied by the saw blade against the material being cut, as with hacksawing machines. The horizontal saw has a spring counterbalance and a sliding weight to adjust the pressure of the blade. When the sliding weight is moved toward the pivot point of the saw frame the band saw blade pressure is reduced. When the weight is moved away from the pivot point, the pressure is increased. The following general principles apply when regulating the feed of horizontal band saw machines.

|

Figure 7-17. Band sawing speeds.

|

Vertical Machine Feeds With vertical machines, the feed is the pressure applied to the saw blade by the material being cut. The workpiece may be hand fed or power fed depending upon the operation to be performed. Cutting curves or special contours requires that the workpiece be guided and fed into the saw blade by hand. The power feed on bandsaw machines is operated by adjustable weights in the machine pedestal. The weights are connected by cables to one of the work-holding attachments of the sawing machine to pull the workpiece against the bandsaw blade. To operate the power feed, the weights are raised by depressing a pedal and the cables are then fixed to the work-holding attachment. When the pedal is released the weights pull the piece into the blade. The following general rules apply to feeding workpieces on bandsawing machines:

COOLANTS Most sawing machines used in military operations are dry cutting machines; that is, they are not intended for use with liquid coolants. However, some power hacksaws and horizontal bandsaws are equipped with a coolant attachment. Soluble oil products, when mixed with water to form emulsions, are used for these machines. This type of coolant has proven very satisfactory for sawing where cooling is an important factor. Most manufacturers of water oil emulsion coolants add a rust inhibitor to the solution to prevent rusting caused by the water in the coolant. |

STRAIGHT-LINE SAWING Straight-line sawing is the most common machine sawing operation. It may be performed using the power hacksaw, horizontal, or vertical band saw. Power Hacksawing The power hacksaw machine is designed primarily for straight-line sawing. A typical sawing operation is outlined below:

|

|

Horizontal Bandsawing Like hacksawing machines, the horizontal bandsaw machine is used primarily for straight-line sawing. The typical sequence of operation for this machine is outlined on next page. Select and install a bandsaw blade of the proper pitch for the type and size of material to be cut.

Vertical Band Saw Operation Straight-line sawing is performed on the vertical band saw machine by using one or a combination of several mechanisms or attachments: the miter guide attachment, with or without power feed, with or without the work-holding jaw device-. and the work-holding jaw device with power feed and angular blade guide attachment.

|

A typical example of straight-line sawing is outlined below :

Start the bandsawing machine and feed the workpiece lightly into the blade to start the cut. Once the cut is started, the feed can be increased. If feeding is by hand, the pressure applied to the workpiece by the operator can be varied to find the best cutting conditions. RADIUS SAWING Radius sawing is performed on the bandsaw by either guiding the workpiece by hand or by using the disk-cutting attachment. Blade Selection Care must be taken to select a bandsaw blade of the proper width for the radius or circle to be cut. If the blade is too wide for the radius, the heel of the blade will press against the outer edge of the kerf (Figure 7-19). When the heel contacts this edge, any further twisting of the workpiece in an attempt to cut a sharper radius will twist the bandsaw blade and may result in the blade breaking. |

|

Figure 7-19. Radius limitation for band saw blade. |

|

Cutting Pressure When cutting a radius, apply a slight side pressure at the inner cutting edge of the bandsaw blade (Figure 7-19). This pressure will give the blade a tendency to provide additional clearance. CONTOUR SAWING Contour sawing is the process of cutting shapes in which the direction of the cut must be changed at intervals. Holes larger in diameter than the width of the saw blade must be drilled at each corner where a change of direction of the bandsaw blade will occur. Figure 7-20 illustrates the methods of changing direction of a cut at a hole. |

Figures 7-20. Methods of sawing to and away from hole.

|

Sawing Away From the Hole tangent to the hole, the saw blade must cut away from the center of the hole, or the blade will bow and cause a belly in the cut. The cut should be started as in A, Figure 7-20, in which a curve is cut outward from the hole to meet the layout line, leaving apiece of excess metal which can be removed later by filing. An alternate method is shown at B, Figure 7-20, in which a section of metal is notched out with a saw blade by several short cuts to give the blade clearance for starting the cut along the layout line. |

Sawing Toward the Hole The diagrams at C and D, Figure 7-20, show the proper method of sawing up to a hole in two cuts. The excess metal can be removed later by tiling. After the shape is cut and the slug or waste material is removed, the comers should be finished by filing or notching. The bandsaw blade should not be used for these operations because the blade will bow and cut unevenly. |

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

No products found