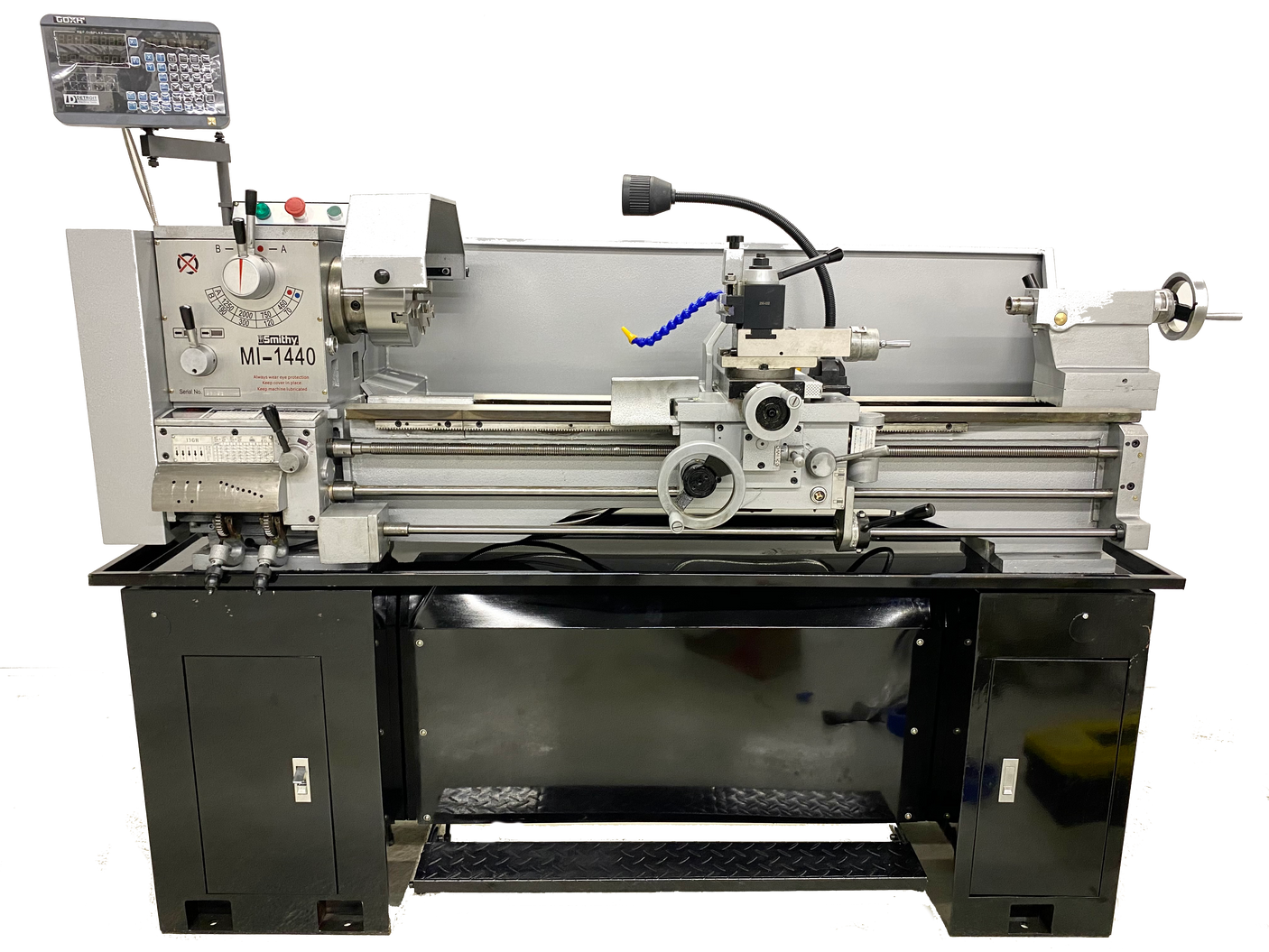

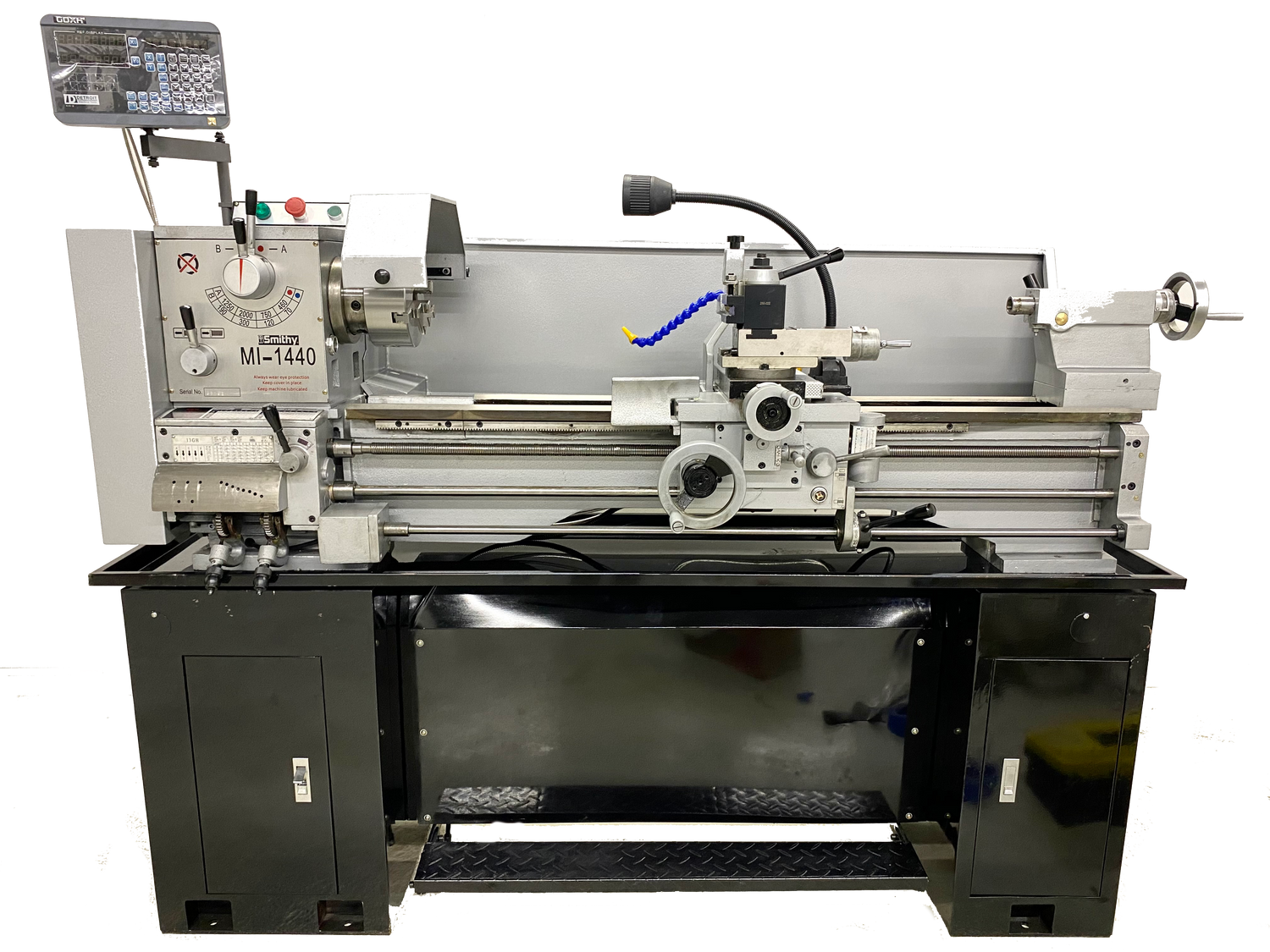

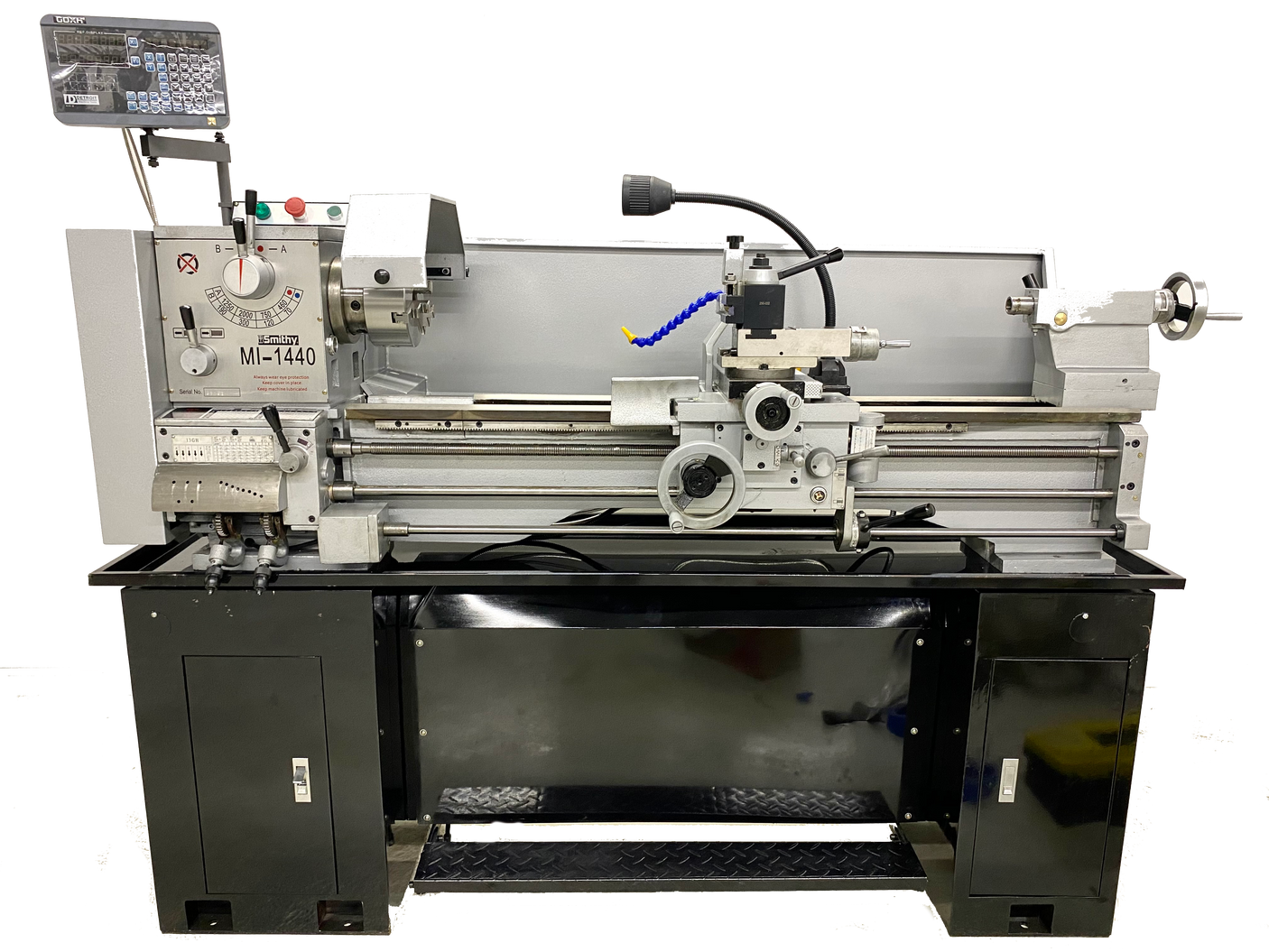

MI-1440 Lathe - 2" Spindle Bore - Norton Gear box

MI-1440 Lathe - 2" Spindle Bore - Norton Gear box is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

Granite - As Close As You'll Get to American Made

1) US Developed and Designed: By Smithy engineers in Ann Arbor, Michigan. Design ideas were based on machine user requests.

2) Higher precision than other combo tools: Granite components are machined to tighter specs - bearings are higher grade - basic design is higher precision.

3) Best Quality Production: Smithy engineers/technicians designed the Granite, and they oversee quality control during production and prior to shipment.

4) Superior Features: You can finish machining tasks -easier and faster- on a Granite machine.

Other 3-in-1 combo tools can't compare to the built-in quality and features of SMITHY tools.

Video Links

Smithy Training Videos - Learning to Machine on a Lathe Mill Combo

Years ago, Smithy produced a series of videos about learning to machine on a lathe mill combo machine. We hear often that these videos have been very helpful. This series is used in quite a few schools and tech training centers, literally throughout the world. Teachers like these videos because the concepts of machining are presented in a very logical way. Hopefully these videos will be helpful to you.

Best Practices - Lathe Turning

Introduction to standard metal late operations. An introduction to basic metal turning concepts is provided, along with basic instructions on lathe operation.

Workholding & Set up

Review of guidelines for installing a variety of work piece types and sizes on a metal lathe. This video covers turning between centers and proper mounting of a work piece in a lathe chuck. Proper use of lathe follow rests and steady rests is included.

Cutting Tool Selection

This video explains the selection and use of single point cutting tools on the lathe. Choosing the right cutting tool for a given operation is an important step when setting up a lathe. Selecting tool types and cutting speeds is also reviewed.

Facing Operations

This video demonstrates proper procedures and operator work process management for lathe turning and facing operations on a metal turning lathe. Reviews the various lathe turning operations that are typically used in a small shop setting.

Bench Top Milling & Drilling

Reviews the concepts of milling and drilling on a metal cutting mill/drill machine. Common practices in milling and drilling operations are presented. Tutorial on selecting best milling and drilling operations for a given task are provided.

Cutting Tool Selection

This video explains the selection and use of end mills and drill bits is covered. Choosing the right cutting tool for a given operation is an important step when setting up for a milling or drilling project. The foundation concept of selecting the best rotating cutting tool and cutting speed for a given project is also reviewed.

Workholding & Set-up

There are a wide variety of workholding tools that can be used to hold a work piece for milling or drilling operations. This video reviews the different concepts and practices in workholding for mill/drill operations. This video also offers some suggestions on workholding accessories to help you get started.

Basic Milling & Drilling Operations

This video starts by showing you machine controls used for milling and drilling operations on a small mill/drill machine. In this case, the Smithy Granite. The video also covers basic concepts and practices for effective metal milling and drilling on a bench top mill/drill machine.

Proper Machine Tool Maintenance

Proper maintenance of every machine tool is the key factor in that machine's ability to machine accurately and efficiently. Lubrication and maintenance are a big factor in assuring long life for every bench top lathe or mill/drill machine.

User Stories

Testimonials from Smithy's happiest customers

No Wait Time With My Smithy

"I have a granite 1324. I run a job shop outfit that does machining work for plastics manufacturing companies. My customers sometimes have orders with 2 or 3 day turn-around. I work in aluminum, plastic, and brass. What I enjoy most about Granite is the lathe work. It is really easy."

-Hai David Nguyen, L.K.B TX

More Convenient for Hobbyists

"I use my Smithy to make or modify parts for motorcycles and antique guns. I'm in this as a hobby. The Smithy probably has paid for itself but I haven't kept track. What is more important to me is the convenience of making my own parts, exactly as I need them when I need them."

-Kerry Klein, MI

Support Leads the Way

"I looked at other machining equipment but chose Smithy because of the quality, size, and availability of tech support. It's compact yet it does the work of larger units. It's a lot of machine that takes up a little space and it will pay for itself in the long run."

-Danny A. KY

Better Than a Grizzly

"After technical school, I did an apprenticeship in clock and watch repair and in tool and die making. I'm retired now and run a busy clock repair shop with my Smithy. I make parts for older clocks, cut clock gears, and make the cutters as well overhaul clock repair tools. I purchased a 9" x 19 bench lathe from Grizzly but returned it because of poor quality. I chose Smithy for its Sturdiness, its milling capabilities, and its compact size."

-William V-R., GA

No more down time

"Wendell and his business partner own a small textile factory. Last year, a German sewing machine clutch broke and production stopped. They weren't sure how long it would take to get a replacement part or if they could even find one. Putting their Smithy to work instead, they had the sewing machine back in production the same day."

-Wendell(Owner of Small Textile Company)

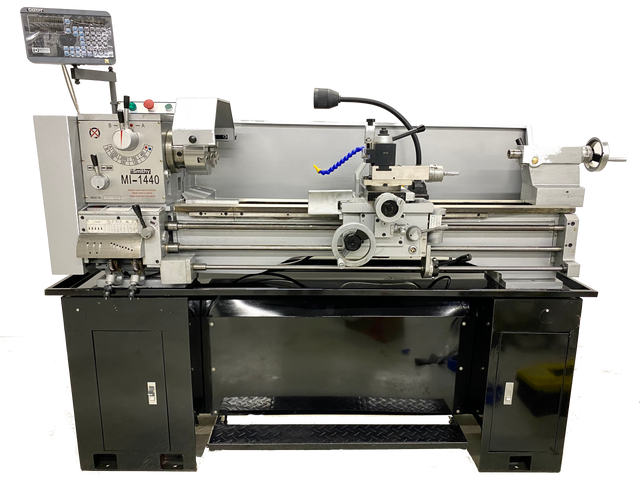

MI- 1440 Lathe - 2" Spindle Bore

Norton Gear Box

High precision and superior repeatability are built-in to this industry heavyweight tool room lathe. Smithy tool room lathes have been out in the field, making parts… and making money for 30 years!

- 14" X 40" Tool Room Lathe

- 2HP, 220/220V

- Heavy Cast Bed - 1100 lbs. of Vibration Damping

- Mass Hand-Scraped, Hardened and Ground Ways - Premium Grade Bearings

**FOR A LIMITED TIME, FREE FACTORY INSTALLED DRO**

OVERVIEW

High Precision, Heavy-Duty 14” X 40” Gear Head Tool Room Lathe

High precision and superior repeatability are built-in to this industry heavyweight tool room lathe. Smithy tool room lathes have been out in the field, making parts… and making money for 30 years. 1100 lbs. heavy cast iron base offers the best foundation for low vibration and high accuracy tool room lathe turning operations. Extra wide way spacing and premium quality bearings add to this durable lathe’s accuracy and long life.

Power feeds, gear driven speed changes and accurate, easy-to-read dials add to this awesome tool room lathe’s ease of use. Don’t forget about Smithy’s 2 year warranty and industry leading parts support.

Product Summary:

- 14” X 40” Tool Room Lathe

- 2 HP 110/220 Volt

- Heavy Cast Bed – 1100 lbs. of Vibration Damping Mass

- Hand-Scraped, Hardened and Ground Ways – With Wide Spacing

- 2" Spindle

- Premium Grade Bearings

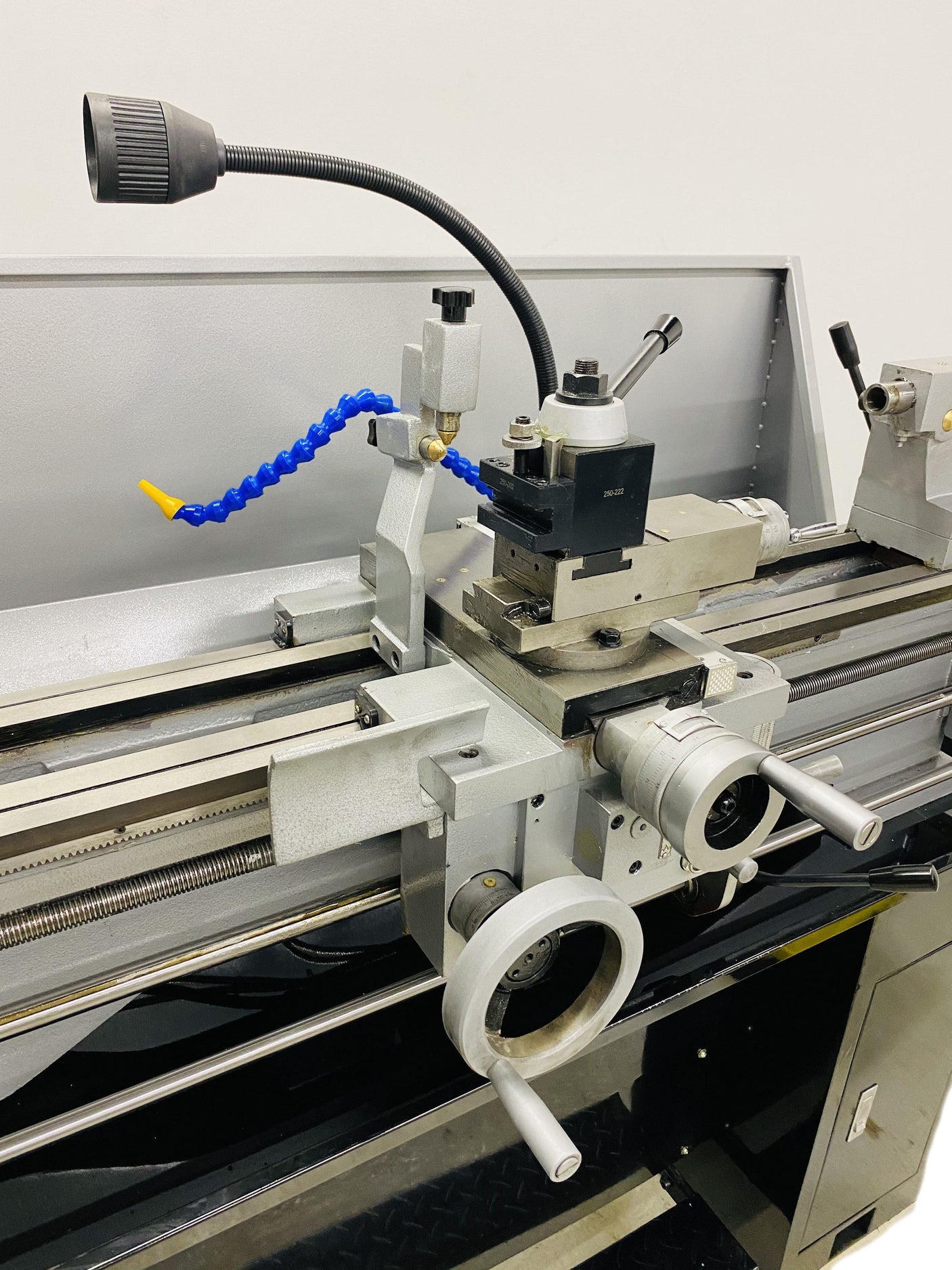

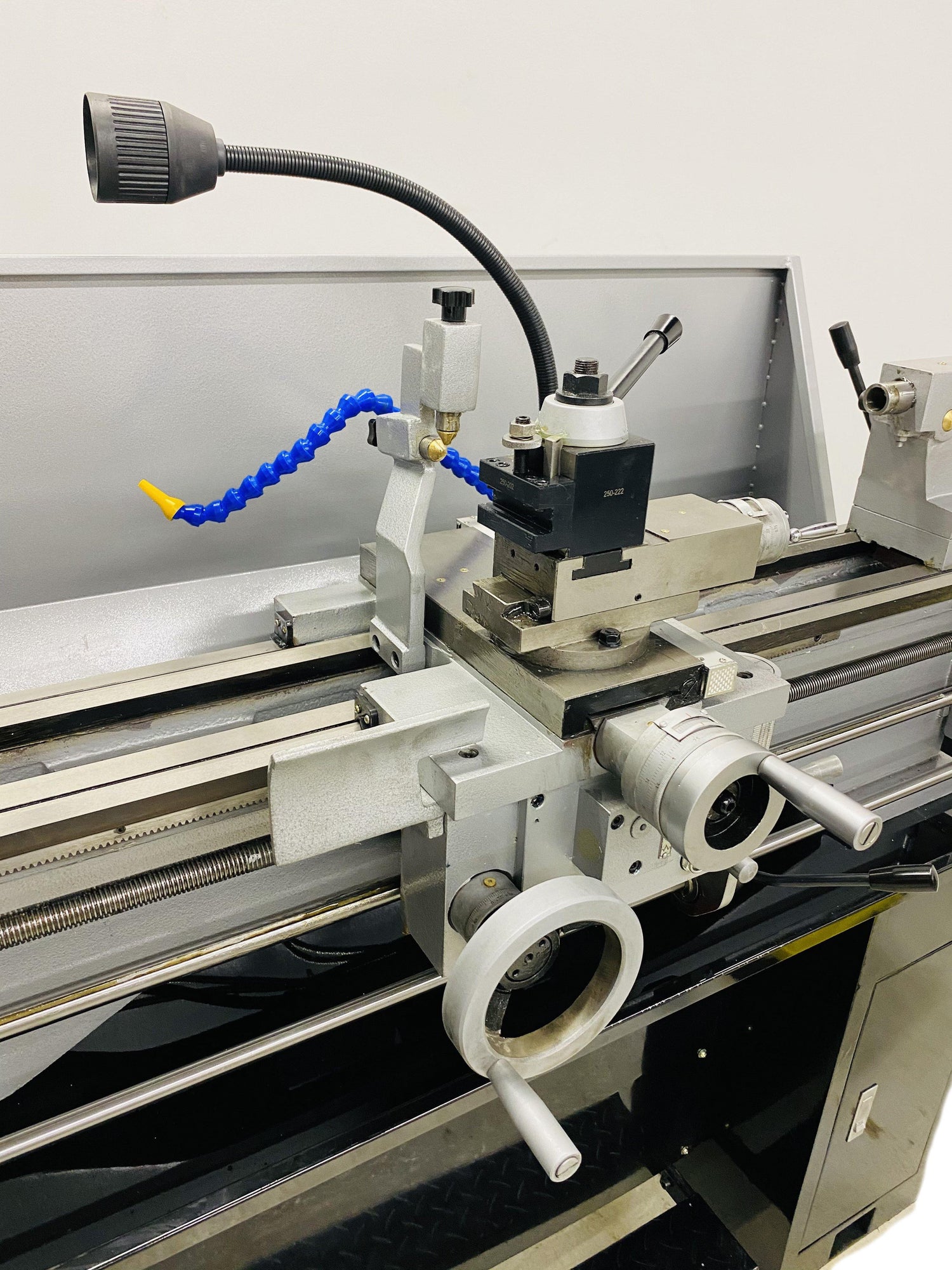

- Includes: FREE Lathe Stand with Foot Brake -more into-

FREE Coolant Pump/Reservoir

($579 Value)

- FREE Quick Change Tool Post ($___ VALUE)

- Industry Standard D1-5 Chuck Mount – Easy Changes

- Powered Screws – Leadscrew and Cross Feed

- Quick Change/Built-In Oil Bath

- High Precision Classic Norton Gear Box -more info-

- Removable Gap – 19 2/3” Swing

- Steady Rest/Follow Rest

- Excellent FREE Tool Pack – Gets you Turning Right Away! -more info-

- See Features and Specs for More Details

Warranty Coverage:

- 2 Years Parts Warranty – PLUS, Industry Leading Smithy Support

SPECS

| Model | MI-1440L |

| Spindle Bore | 2.0" |

| Motor Size | 2 HP |

| Electrical Requirements | 110 VAC or 220 VAC (Convertible) |

| Amperage | 9 Amps @ 220 Volt / 18 Amps @ 110 Volts |

| Chuck Size (3 And 4 Jaw) | 6" 3-Jaw and 8" 4-Jaw (2" Chuck Bore on both) |

| Chuck Mounting | Industrial Standard "D1-4" |

| Swing Over Bed | 13.90" |

| Swing Over Carriage | 8.75" |

| Swing With Gap Section Removed | 19.68" |

| Distance Between Centers | 40" |

| Headstock, Gearbox, & Apron Lubrication | Oil Bath with Reservoir and Site Gauge |

| Handles, Hand Wheels & Levers | Metal Construction, No Plastic |

| Work Light | Standard |

| Stand With Drip Pan & Splash Shield | Standard |

| Spindle Guard | Standard |

ELECTRICAL SPECIFICATIONS

| Model | MI-1440L |

| Power Requirements | 110V/220VAC, Single Phase (Convertible) |

| Connection Type | Plug & Cord |

| Plug | 6-15P 220 Volt (supplied), 5-15P 110 Volt (not supplied) |

| Outlet | 5-15R for 110 VAC, 6-15R for 220 VAC |

| Motor Type | Induction Type A/C |

| Motor Power | 2 HP |

| Motor Amp Draw | 18 Amps @ 110 VAC / 9 Amps @ 220 VAC |

MECHANICAL SPECIFICATIONS

| Model | MI-1440L |

| Spindle Speed Control | Mechanical |

| Number Of Speeds | 8 |

| Available Speed | 84, 140, 230, 360, 430, 700, 1150, 1850 |

| Longitudinal Travel | 33" |

| Cross Travel | 6.3" |

| Compound Travel | 2.76" |

| Tailstock Barrel Travel | 3.74" |

| Tailstock Taper | MT3 |

| Distance Between Centers | 40" |

| Swing Over Carriage | 8.75" |

| Swing Over Bed | 13.75" |

| Swing Over Removable Gap | 19.68" |

| Spindle And Chuck Bore Diameter | Allows 1.50" Bar Stock |

| Spindle Nose Taper | MT5 |

| Spindle Nose | D1-4 |

| 3-Jaw Chuck Diameter | 8" |

| 4-Jaw Chuck Diameter | 8" |

| Feed Screw Pitch | 8 TPI |

| Longitudinal Feed Rates | 0.002”-0.0548”/ rev |

| Cross Feed Rates | 0.0007”-0.187”/rev |

| Number Of Inch Threads | 34 |

| Inch Thread Pitches | 4 to 112 TPI |

| Number Of Metric Threads | 26 |

| Metric Thread Pitches | .04 to 7.0mm |

| Tool Size | 1/2” or 5/8” |

PHYSICAL DIMENSIONS

| Model | MI-1440L |

| Machine Weight | 1114 lbs |

| Machine Size | 26" W x 26" H x 70" L |

| Shipping Weight | 1245 lbs |

| Shipping Crate Size | 30” W x 36" H x 76" L |

| Shipping Crate Material | Wood |

VIDEOS

FAQS

OVERVIEW

High Precision, Heavy-Duty 14” X 40” Gear Head Tool Room Lathe

High precision and superior repeatability are built-in to this industry heavyweight tool room lathe. Smithy tool room lathes have been out in the field, making parts… and making money for 30 years. 1100 lbs. heavy cast iron base offers the best foundation for low vibration and high accuracy tool room lathe turning operations. Extra wide way spacing and premium quality bearings add to this durable lathe’s accuracy and long life.

Power feeds, gear driven speed changes and accurate, easy-to-read dials add to this awesome tool room lathe’s ease of use. Don’t forget about Smithy’s 2 year warranty and industry leading parts support.

Product Summary:

- 14” X 40” Tool Room Lathe

- 2 HP 110/220 Volt

- Heavy Cast Bed – 1100 lbs. of Vibration Damping Mass

- Hand-Scraped, Hardened and Ground Ways – With Wide Spacing

- Premium Grade Bearings

- Includes: FREE Lathe Stand with Foot Brake -more into-

FREE Coolant Pump/Reservoir

($579 Value)

- FREE Quick Change Tool Post ($___ VALUE)

- Industry Standard D1-5 Chuck Mount – Easy Changes

- Powered Screws – Leadscrew and Cross Feed

- Quick Change/Built-In Oil Bath

- High Precision Classic Norton Gear Box -more info-

- Removable Gap – 19 2/3” Swing

- Steady Rest/Follow Rest

- Excellent FREE Tool Pack – Gets you Turning Right Away! -more info-

- See Features and Specs for More Details

Warranty Coverage:

- 2 Years Parts Warranty – PLUS, Industry Leading Smithy Support

SPECS

| Model | MI-1440L |

| Spindle Bore | 1.5" |

| Motor Size | 2 HP |

| Electrical Requirements | 110 VAC or 220 VAC (Convertible) |

| Amperage | 9 Amps @ 220 Volt / 18 Amps @ 110 Volts |

| Chuck Size (3 And 4 Jaw) | 6" 3-Jaw and 8" 4-Jaw (2" Chuck Bore on both) |

| Chuck Mounting | Industrial Standard "D1-4" |

| Swing Over Bed | 13.90" |

| Swing Over Carriage | 8.75" |

| Swing With Gap Section Removed | 19.68" |

| Distance Between Centers | 40" |

| Headstock, Gearbox, & Apron Lubrication | Oil Bath with Reservoir and Site Gauge |

| Handles, Hand Wheels & Levers | Metal Construction, No Plastic |

| Work Light | Standard |

| Stand With Drip Pan & Splash Shield | Standard |

| Spindle Guard | Standard |

ELECTRICAL SPECIFICATIONS

| Model | MI-1440L |

| Power Requirements | 110V/220VAC, Single Phase (Convertible) |

| Connection Type | Plug & Cord |

| Plug | 6-15P 220 Volt (supplied), 5-15P 110 Volt (not supplied) |

| Outlet | 5-15R for 110 VAC, 6-15R for 220 VAC |

| Motor Type | Induction Type A/C |

| Motor Power | 2 HP |

| Motor Amp Draw | 18 Amps @ 110 VAC / 9 Amps @ 220 VAC |

MECHANICAL SPECIFICATIONS

| Model | MI-1440L |

| Spindle Speed Control | Mechanical |

| Number Of Speeds | 8 |

| Available Speed | 84, 140, 230, 360, 430, 700, 1150, 1850 |

| Longitudinal Travel | 33" |

| Cross Travel | 6.3" |

| Compound Travel | 2.76" |

| Tailstock Barrel Travel | 3.74" |

| Tailstock Taper | MT3 |

| Distance Between Centers | 40" |

| Swing Over Carriage | 8.75" |

| Swing Over Bed | 13.75" |

| Swing Over Removable Gap | 19.68" |

| Spindle And Chuck Bore Diameter | Allows 1.50" Bar Stock |

| Spindle Nose Taper | MT5 |

| Spindle Nose | D1-4 |

| 3-Jaw Chuck Diameter | 8" |

| 4-Jaw Chuck Diameter | 8" |

| Feed Screw Pitch | 8 TPI |

| Longitudinal Feed Rates | 0.002”-0.0548”/ rev |

| Cross Feed Rates | 0.0007”-0.187”/rev |

| Number Of Inch Threads | 34 |

| Inch Thread Pitches | 4 to 112 TPI |

| Number Of Metric Threads | 26 |

| Metric Thread Pitches | .04 to 7.0mm |

| Tool Size | 1/2” or 5/8” |

PHYSICAL DIMENSIONS

| Model | MI-1440L |

| Machine Weight | 1114 lbs |

| Machine Size | 26" W x 26" H x 70" L |

| Shipping Weight | 1245 lbs |

| Shipping Crate Size | 30” W x 36" H x 76" L |

| Shipping Crate Material | Wood |

-

Lathe Specifications

MI-1440 Tool Room Lathe – Unique Features:14” Swing – 40” Centers

Turn material up to 14” in diameter over the bed – Turn material up to 40” between centers

2 HP - 110/220

Solid, reliable power – optional set-up for 110V or 220V.

Super Heavy Castings – Weighs over 1100 lbs.

Base castings weighing over 1100 lbs. provides the ultimate foundation for high precision and long operating life.

Extra Wide Bed Ways

Extra width between bed ways assures maximum accuracy and ruggedness for work table movement and operation.

Premium Grade Bearings

High accuracy and repeatability are unquestioned. Long operating life is guaranteed.

D1-5 Chuck – Fast, Easy Changes

Industry standard D1-4 chuck mount allows for quick changes of chucks, plates and other mounting systems.

Removable Gap – 19 2/3” Swing

Removing the gap plug allows you to turn larger diameter work piecies – up to 17-3/4” in diameter.

Smithy Lathe Standard Features:Hardened, Ground & Hand-Scraped Ways

Induction hardened, precision ground and hand-scraped ways provide the ultimate in accuracy and repeatability.

Gear Drive Power Train

Heavy cast gears put power directly to the spindle, assuring maximum torque.

E-Z Operator Spindle Control

Neutral, Forward, and Reverse buttons are conveniently located on machine apron, along with all dials and gear shifters, offering reliable operator convenience.

Powered Feeds – Lead Screw and Cross Feed

Power feed out performs manual feed for precision and smooth, accurate finishes.

Norton Style Gear Box

30 years of selling lathes at Smithy has shown the US Developed Standard Norton style gear box to be, by far, the most accurate for lathe machines built with inch gears and components. We also specify the Norton gear box because it has proven to be superior for maintenance, durability and ease of use.

Large Spindle Bore

Allows 1.5” bar stock to pass through lathe head stock.

Offset Tailstock

Manual offset and lockdown allows for cutting tapers.

Threading Dial and Half Nut

Makes for easy thread cutting and chasing operations.

Thread Cutting

Cuts a variety of right hand and left hand threads. Also, inch and metric. Has change gears for metric thread cutting operations.

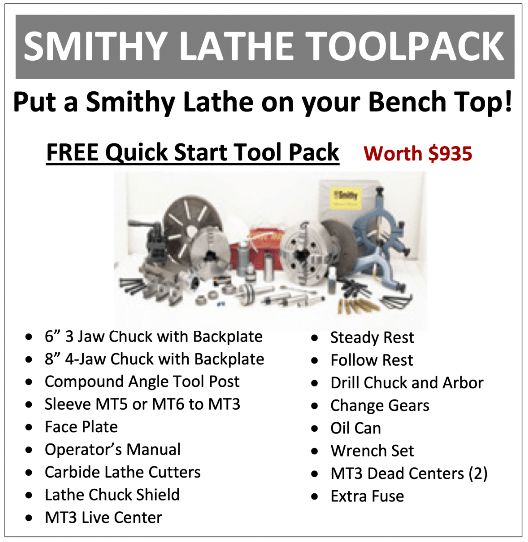

FREE Tool Pack Features:Quick Change Tool Post

Once cutters are mounted in individual tool mounting blocks, changing out different tools can be accomplished quickly and easily, while maintaining high accuracy. Helps speed up machining operations.

6” 3-Jaw Chuck

Includes two sets of jaws – inside and outside. The correct back plate to match the machine is pre-installed on the chuck.

8” 4-Jaw Chuck

Heavy and solid to support operations that require interrupted cuts. Reversible jaws are able to grip work pieces in multiple configurations. The correct back plate to match the machine is pre-installed on the chuck.

12” Faceplate

Plenty of surface area to mount uniquely shaped work pieces – use with lathe dogs as a drive plate.

Chuck GuardIncluded OSHA required and approved lathe chuck guard.Steady Rest/Follow Rest

An important accessory for supporting extra-long or flexible work pieces – allows for the safe and smooth cutting of pieces that don’t within standard mounting procedures.

Financing Options

Consumer / Personal Financing

- 48-month financing plan

- 5.99% interest rate

- Promotional Financing Plan only when purchasing Smithy equipment

Commercial / Business Financing

- Soft-pull credit - doesn't affect credit score

- Flexible rates and payment plans

- Approval with low credut

Canada - Business Financing

- Soft-pull on credit - doesn't affect credit score

- Flexible rates and payment plans

- Approval with low credit

WHO BUYS THESE SMITHY LATHES?

Schools purchase quite a few. Military organizations, R & D labs, and small machine shop/production shops are frequent buyers. The machines are designed and built to be good enough to use in parts production settings - the reality is that, because the price is so reasonable, these lathes are popular for the home shop buyer.

IS THE TOOL PACK HELPFUL?

The FREE tool pack is intended to give you a basic tool set-up to get you started when you get the machine. It’s a balanced set of tooling, but you will likely need more tooling once you figure out specific projects you want to do.

WHAT DO YOU MEAN BY “INSPECTED TWICE?”

Each lathe is inspected by trained company employees at the factory - PLUS, a second complete inspection is performed at our warehouse in Ann Arbor, MI before it is sent to the customer.

WHY ARE THESE LATHES BETTER THAN OTHERS ON THE MARKET?

For a machine tool to be truly great it must have attention paid to every step of its development - design, production, quality control, testing, and after sales support. Other benchtop lathes you'll find typically don't have this level of quality committed to every step like these MIDAS lathes.

HOW LONG HAVE YOU BEEN SELLING THESE LATHES?

Over 30 Years.

DO MANY LATHE BUYERS ALSO PURCHASE MILLING MACHINES?

Yes, the MI-1337L lathe matches well with the MI-329MZ milling machine - a machine shop combo that was built to last. Many customers buy this combination.

WHY SHOULD I BUY A SMITHY LATHE?

Rugged Design

Quality Built-In

Inspected Twice

Best Service, Warranty & Support

The best gear drive lathe value - for over 30 years!

DO I NEED TO BE A MACHINIST TO USE THE MACHINE?

Many buyers of these lathes don’t have machining/turning experience - what they have is the need to make parts. Usually they already have something in mind they need to make. What is needed is a commitment to learn and curiosity. It will take time, but you will figure it out. We have a set of machining training videos on our website - you can usually find classes at a local community college or vo-tech school. Get a machine and get going! You won’t be disappointed.

The machines are designed and built to be good enough to use in parts production settings - the reality is that, because the price is so reasonable, these lathes are popular for the home shop buyer.

**PICTURED MACHINE IS SHOWN WITH OPTIONAL DRO**

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.