VMC425 - VERTICAL MACHINING CENTER -

VMC425 - VERTICAL MACHINING CENTER - is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

Video Links

Smithy Training Videos - Learning to Machine on a Lathe Mill Combo

Years ago, Smithy produced a series of videos about learning to machine on a lathe mill combo machine. We hear often that these videos have been very helpful. This series is used in quite a few schools and tech training centers, literally throughout the world. Teachers like these videos because the concepts of machining are presented in a very logical way. Hopefully these videos will be helpful to you.

Best Practices - Lathe Turning

Introduction to standard metal late operations. An introduction to basic metal turning concepts is provided, along with basic instructions on lathe operation.

Workholding & Set up

Review of guidelines for installing a variety of work piece types and sizes on a metal lathe. This video covers turning between centers and proper mounting of a work piece in a lathe chuck. Proper use of lathe follow rests and steady rests is included.

Cutting Tool Selection

This video explains the selection and use of single point cutting tools on the lathe. Choosing the right cutting tool for a given operation is an important step when setting up a lathe. Selecting tool types and cutting speeds is also reviewed.

Facing Operations

This video demonstrates proper procedures and operator work process management for lathe turning and facing operations on a metal turning lathe. Reviews the various lathe turning operations that are typically used in a small shop setting.

Bench Top Milling & Drilling

Reviews the concepts of milling and drilling on a metal cutting mill/drill machine. Common practices in milling and drilling operations are presented. Tutorial on selecting best milling and drilling operations for a given task are provided.

Cutting Tool Selection

This video explains the selection and use of end mills and drill bits is covered. Choosing the right cutting tool for a given operation is an important step when setting up for a milling or drilling project. The foundation concept of selecting the best rotating cutting tool and cutting speed for a given project is also reviewed.

Workholding & Set-up

There are a wide variety of workholding tools that can be used to hold a work piece for milling or drilling operations. This video reviews the different concepts and practices in workholding for mill/drill operations. This video also offers some suggestions on workholding accessories to help you get started.

Basic Milling & Drilling Operations

This video starts by showing you machine controls used for milling and drilling operations on a small mill/drill machine. In this case, the Smithy Granite. The video also covers basic concepts and practices for effective metal milling and drilling on a bench top mill/drill machine.

Proper Machine Tool Maintenance

Proper maintenance of every machine tool is the key factor in that machine's ability to machine accurately and efficiently. Lubrication and maintenance are a big factor in assuring long life for every bench top lathe or mill/drill machine.

User Stories

Testimonials from Smithy's happiest customers

No Wait Time With My Smithy

"I have a granite 1324. I run a job shop outfit that does machining work for plastics manufacturing companies. My customers sometimes have orders with 2 or 3 day turn-around. I work in aluminum, plastic, and brass. What I enjoy most about Granite is the lathe work. It is really easy."

-Hai David Nguyen, L.K.B TX

More Convenient for Hobbyists

"I use my Smithy to make or modify parts for motorcycles and antique guns. I'm in this as a hobby. The Smithy probably has paid for itself but I haven't kept track. What is more important to me is the convenience of making my own parts, exactly as I need them when I need them."

-Kerry Klein, MI

Support Leads the Way

"I looked at other machining equipment but chose Smithy because of the quality, size, and availability of tech support. It's compact yet it does the work of larger units. It's a lot of machine that takes up a little space and it will pay for itself in the long run."

-Danny A. KY

Better Than a Grizzly

"After technical school, I did an apprenticeship in clock and watch repair and in tool and die making. I'm retired now and run a busy clock repair shop with my Smithy. I make parts for older clocks, cut clock gears, and make the cutters as well overhaul clock repair tools. I purchased a 9" x 19 bench lathe from Grizzly but returned it because of poor quality. I chose Smithy for its Sturdiness, its milling capabilities, and its compact size."

-William V-R., GA

No more down time

"Wendell and his business partner own a small textile factory. Last year, a German sewing machine clutch broke and production stopped. They weren't sure how long it would take to get a replacement part or if they could even find one. Putting their Smithy to work instead, they had the sewing machine back in production the same day."

-Wendell(Owner of Small Textile Company)

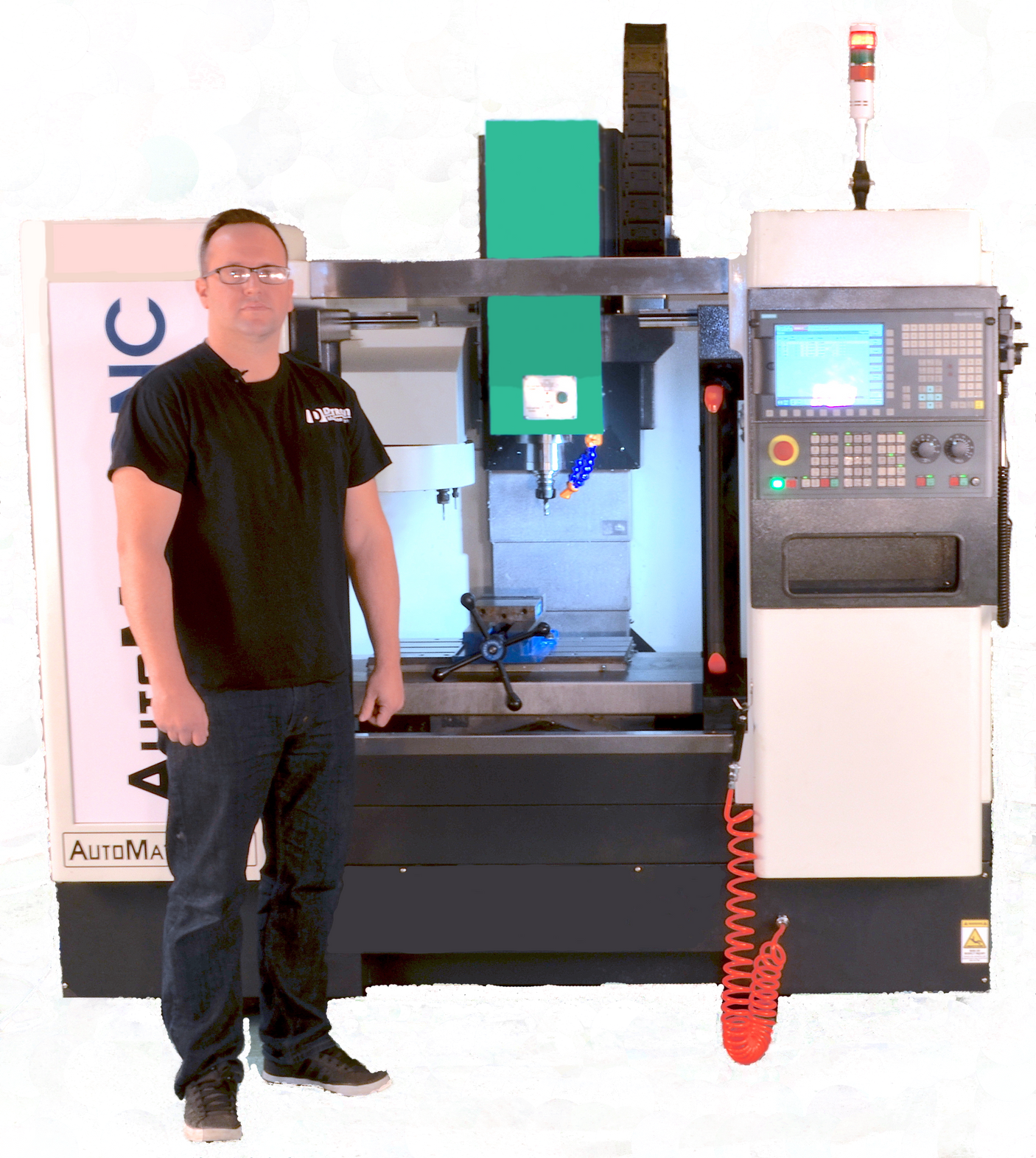

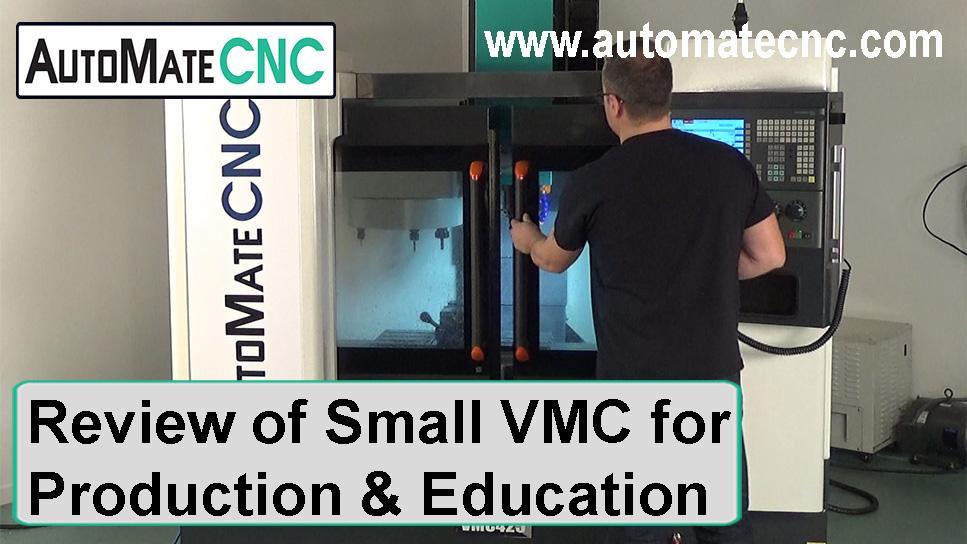

VMC425, 7.5 HP Servo Spindle

Full Production Capacity - Small Footprint

- Closed Loop System/Servos: Industrial level of power, precision and performance.

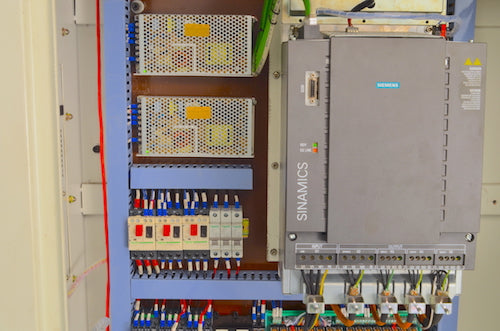

- Siemens 808D CNC Control: Industrial grade CNC control with conversational programming and on-screen help guide.

- 7.5 HP Servo Spindle Motor: High torque, even at low RPMs - constant torque rise through speed range. Allows for rigid tapping and spindle positioning.

- 50-8000 RPM Spindle: Ramp up from lowest to highest speed at the push of a button.

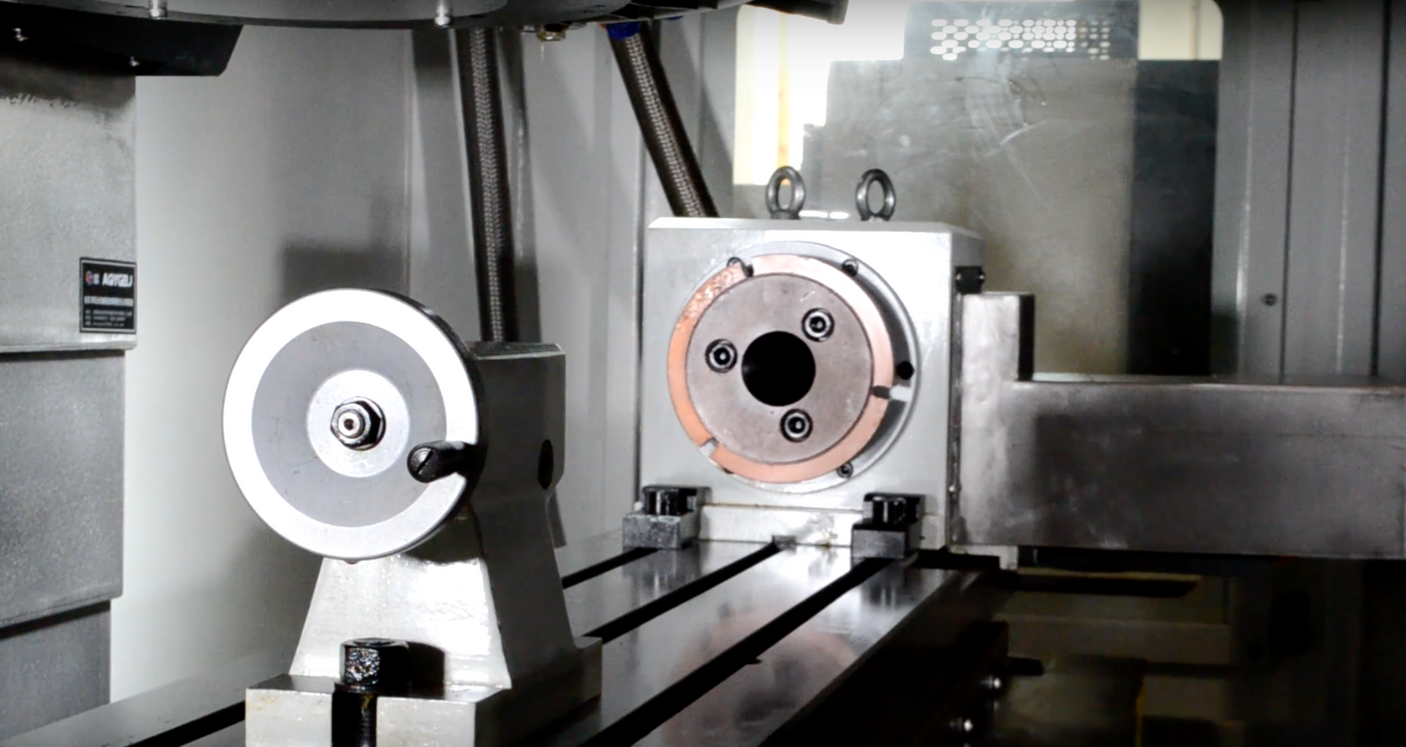

- 10 Tool Automatic Tool Change System: Automated milling operations with precision BT30 10-tool ATC. Change tools by hand fast with pnuematic "push-button" tool change.

- High Quality Linear Guides and Ball Screws: Increased precision and higher speed operations. Allows for 1000 IPM feed rates.

- Full Enclosure: Full "Safety-Lock" enclosure keeps operator safe - contains coolant and chips during long production runs.

- Heavy Base and Machine Castings: Optimal vibration damping, assuring consistent precision and excellent repeatability.

| OVERVIEW | FEATURES | SPECS |