FL300 - FLAT BED CNC GANG TOOL LATHE -

FL300 - FLAT BED CNC GANG TOOL LATHE - is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

Video Links

Smithy Training Videos - Learning to Machine on a Lathe Mill Combo

Years ago, Smithy produced a series of videos about learning to machine on a lathe mill combo machine. We hear often that these videos have been very helpful. This series is used in quite a few schools and tech training centers, literally throughout the world. Teachers like these videos because the concepts of machining are presented in a very logical way. Hopefully these videos will be helpful to you.

Best Practices - Lathe Turning

Introduction to standard metal late operations. An introduction to basic metal turning concepts is provided, along with basic instructions on lathe operation.

Workholding & Set up

Review of guidelines for installing a variety of work piece types and sizes on a metal lathe. This video covers turning between centers and proper mounting of a work piece in a lathe chuck. Proper use of lathe follow rests and steady rests is included.

Cutting Tool Selection

This video explains the selection and use of single point cutting tools on the lathe. Choosing the right cutting tool for a given operation is an important step when setting up a lathe. Selecting tool types and cutting speeds is also reviewed.

Facing Operations

This video demonstrates proper procedures and operator work process management for lathe turning and facing operations on a metal turning lathe. Reviews the various lathe turning operations that are typically used in a small shop setting.

Bench Top Milling & Drilling

Reviews the concepts of milling and drilling on a metal cutting mill/drill machine. Common practices in milling and drilling operations are presented. Tutorial on selecting best milling and drilling operations for a given task are provided.

Cutting Tool Selection

This video explains the selection and use of end mills and drill bits is covered. Choosing the right cutting tool for a given operation is an important step when setting up for a milling or drilling project. The foundation concept of selecting the best rotating cutting tool and cutting speed for a given project is also reviewed.

Workholding & Set-up

There are a wide variety of workholding tools that can be used to hold a work piece for milling or drilling operations. This video reviews the different concepts and practices in workholding for mill/drill operations. This video also offers some suggestions on workholding accessories to help you get started.

Basic Milling & Drilling Operations

This video starts by showing you machine controls used for milling and drilling operations on a small mill/drill machine. In this case, the Smithy Granite. The video also covers basic concepts and practices for effective metal milling and drilling on a bench top mill/drill machine.

Proper Machine Tool Maintenance

Proper maintenance of every machine tool is the key factor in that machine's ability to machine accurately and efficiently. Lubrication and maintenance are a big factor in assuring long life for every bench top lathe or mill/drill machine.

User Stories

Testimonials from Smithy's happiest customers

No Wait Time With My Smithy

"I have a granite 1324. I run a job shop outfit that does machining work for plastics manufacturing companies. My customers sometimes have orders with 2 or 3 day turn-around. I work in aluminum, plastic, and brass. What I enjoy most about Granite is the lathe work. It is really easy."

-Hai David Nguyen, L.K.B TX

More Convenient for Hobbyists

"I use my Smithy to make or modify parts for motorcycles and antique guns. I'm in this as a hobby. The Smithy probably has paid for itself but I haven't kept track. What is more important to me is the convenience of making my own parts, exactly as I need them when I need them."

-Kerry Klein, MI

Support Leads the Way

"I looked at other machining equipment but chose Smithy because of the quality, size, and availability of tech support. It's compact yet it does the work of larger units. It's a lot of machine that takes up a little space and it will pay for itself in the long run."

-Danny A. KY

Better Than a Grizzly

"After technical school, I did an apprenticeship in clock and watch repair and in tool and die making. I'm retired now and run a busy clock repair shop with my Smithy. I make parts for older clocks, cut clock gears, and make the cutters as well overhaul clock repair tools. I purchased a 9" x 19 bench lathe from Grizzly but returned it because of poor quality. I chose Smithy for its Sturdiness, its milling capabilities, and its compact size."

-William V-R., GA

No more down time

"Wendell and his business partner own a small textile factory. Last year, a German sewing machine clutch broke and production stopped. They weren't sure how long it would take to get a replacement part or if they could even find one. Putting their Smithy to work instead, they had the sewing machine back in production the same day."

-Wendell(Owner of Small Textile Company)

PRODUCT INFO

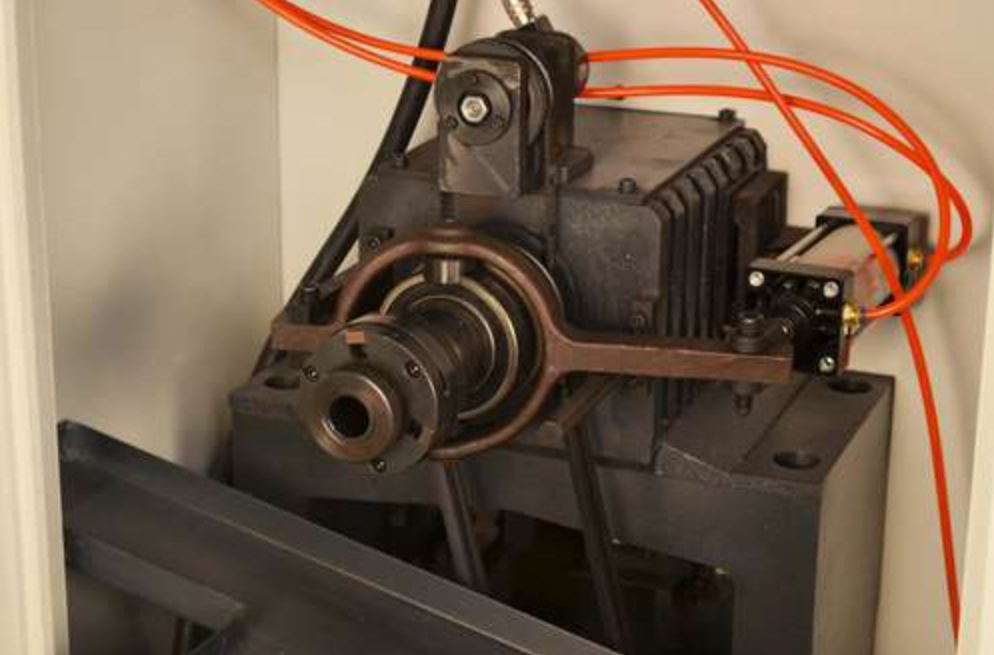

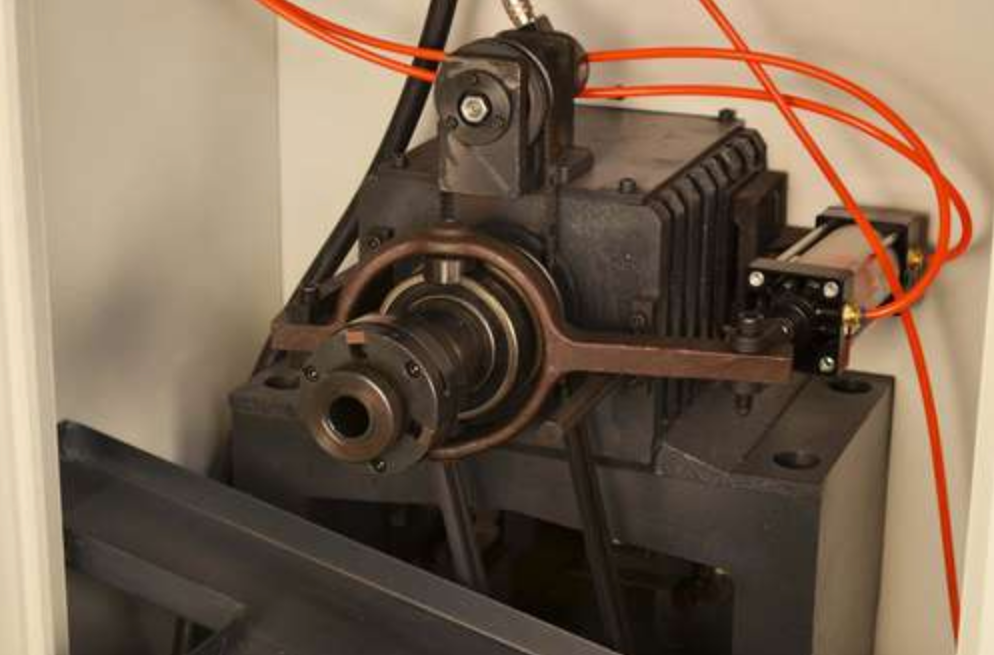

5 HP Servo Spindle

OVERVIEW

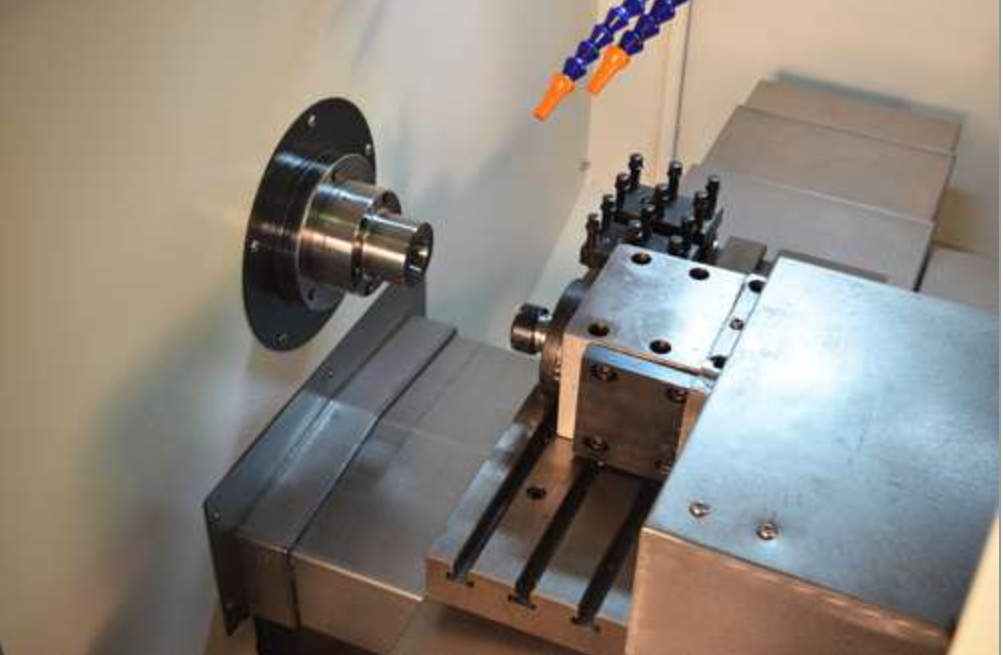

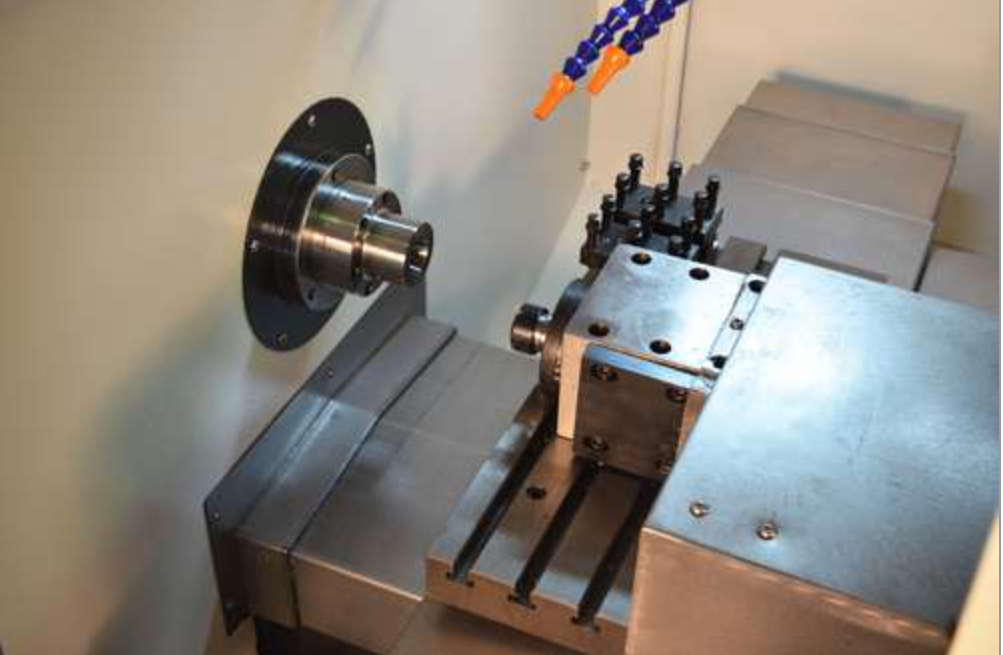

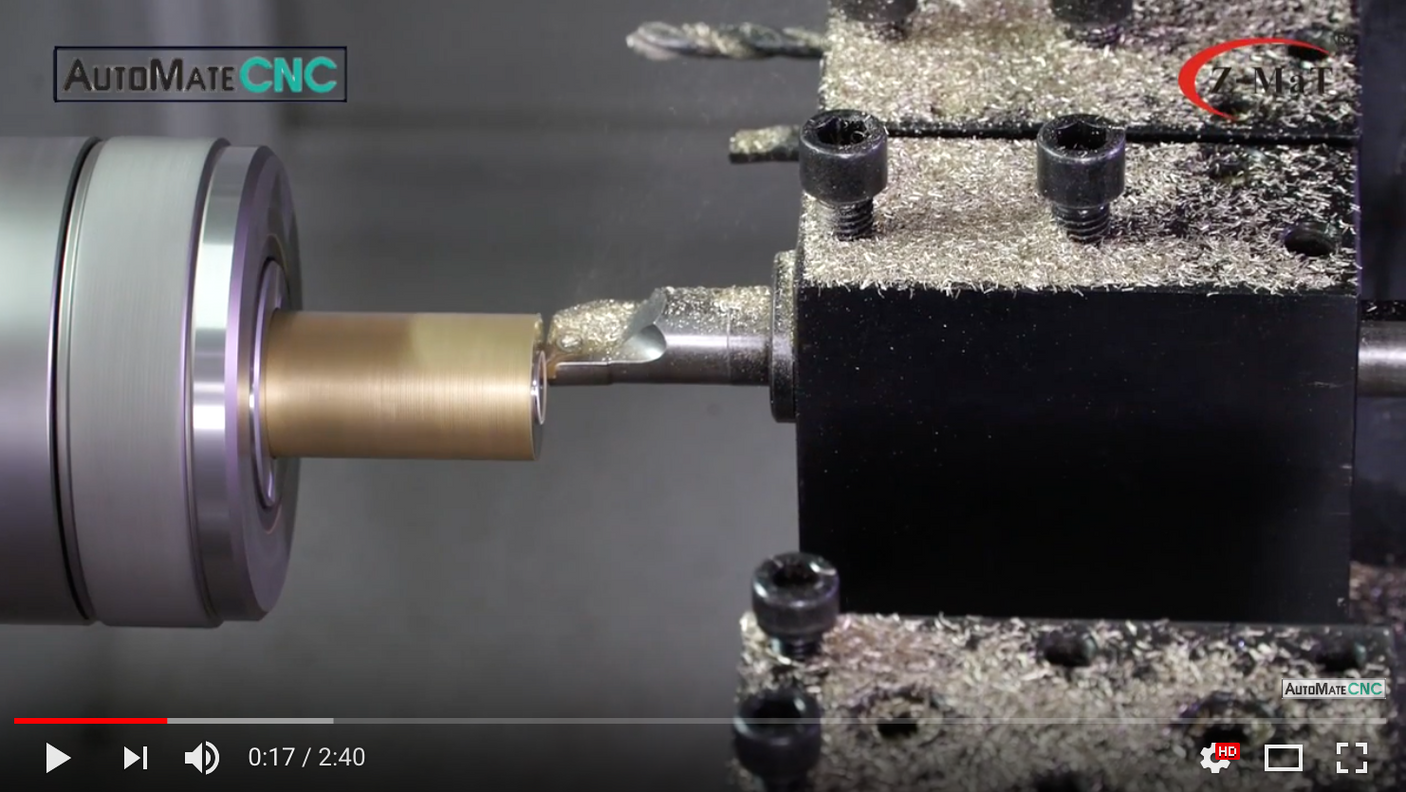

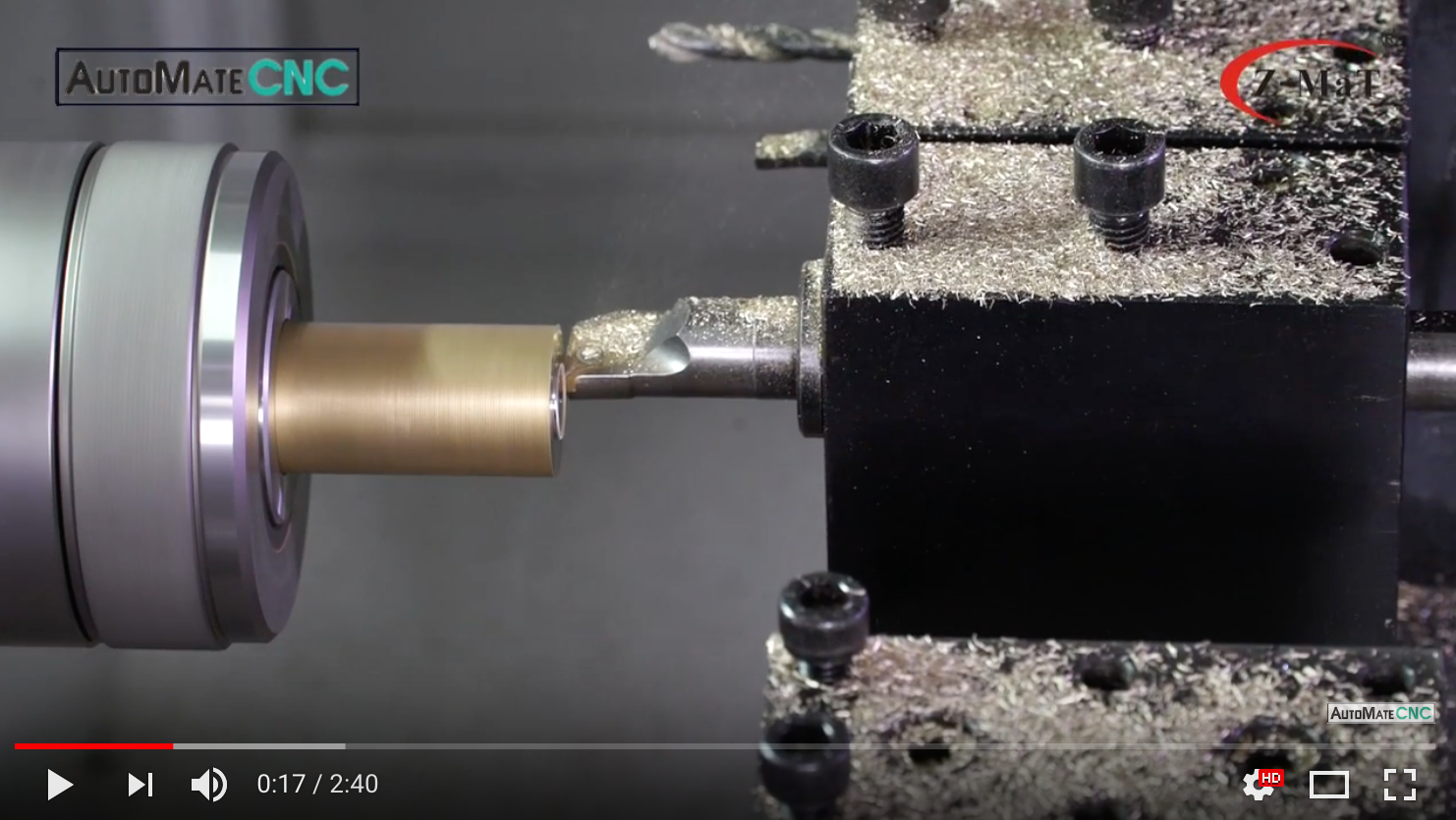

Flat Bed CNC Gang Tool Lathe

The FL300 offers the optimum combination of value price, accuracy, speed and production capacity. This lathe is the the factory's most popular model. Why? It's fast, powerful and has a lot of capacity - It offers the most bang for the buck!

The extra long table and 14" X axis travel is industry best for tooling capacity. Rapid feed rates of up to 1000 IPM are possible with world-class quality ball screws and linear ways.

A pneumatic collet system with foot actuator, ergonomic control, and digital handwheel are a few of the features that make this low cost gang tool lathe one of the best deals for volume production CNC lathes.

Designed for low cost and volume production applications, this lathe is also used widely in education, machine shops, home shops and second operation settings.

- Siemens 808D CNC Control

- Servo Motors and Drives on X/Z

- Closed Loop System

- Pneumatic Collet System

- Extra Long Gang Table

- 14" Cross-Feed Travel

- 50-3000 Spindle RPM

- 5 HP Servo Spindle

- Travel: X = 12”/Y = 16”

- Feed Rate: X=1000 IPM / Z=600 IPM

- Efficient Ergonomic Design

- 18 months on the FL300

- 3 years total (2+1) on the Siemens 808D Control

FEATURES

| Lathe Machine | |

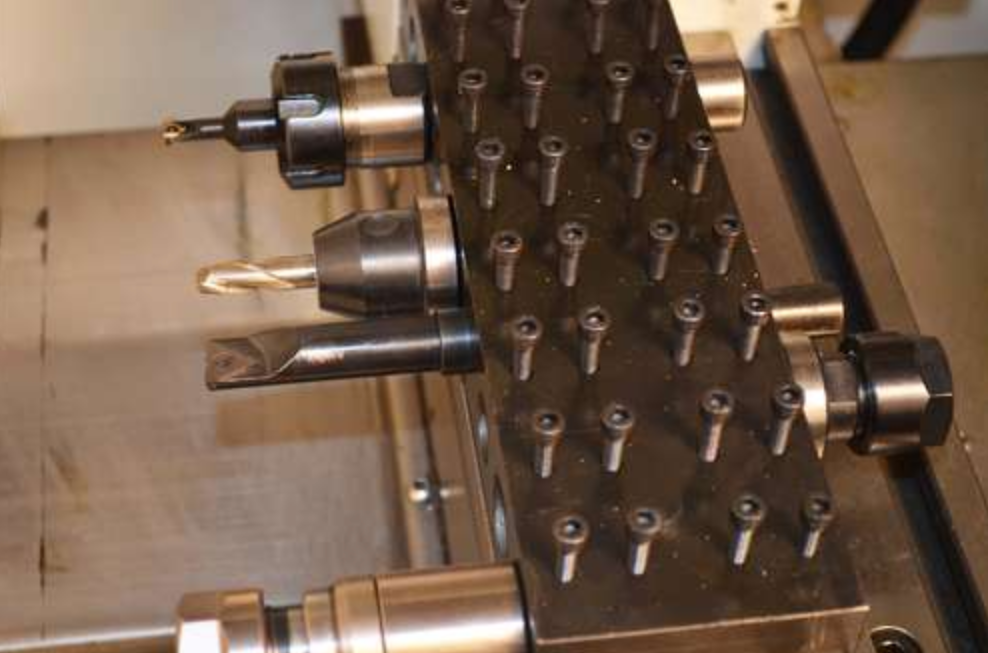

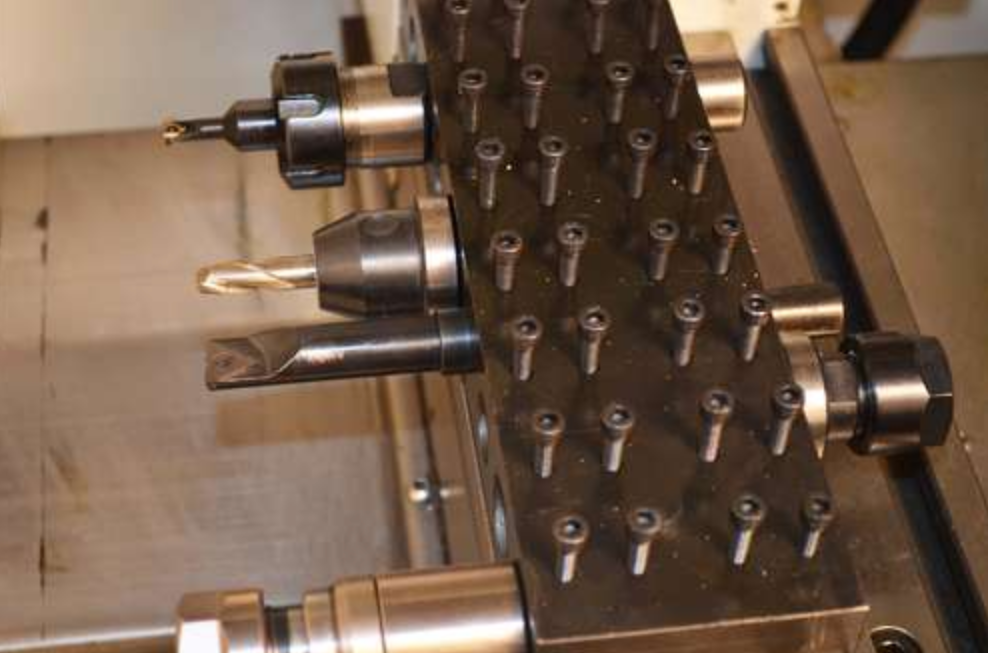

| Extra Large Table and Long X Axis | Large work table and a long X axis stroke allows for a large number of gang tool blocks, plus live tooling. Offers more flexibility and variation in tooling and turning set-ups. Many live tooling options available. |

| Heavy Castings with Cast Base | Compact, rigid machine design - weighing over 2600 lbs. High weight-to-work cube ratio assures high rigidity, even when taking heavy cuts. |

| Full Enclosure | Machine is completely enclosed with a sliding front access door and easy access panels on the tailstock end and machine back side. Coolant and chips are enclosed and properly recycled. Electromagnetic lock keeps operator safe. |

| 1.46” Spindle Bore | Easy access for standard pneumatic collet system. Optional hydrualic system, and collet system available. Adaptable for automatic bar feeder, and live tooling. |

| Gang Tool Plate | A nice set of tool holders is included with this lathe tool pack. Gang tool turning is the fastest, simplest, and most economical of turning methods. Generally limited to smaller diameter part material - less than 2”. |

| Pneumatic Collet Closer with Auxiliary Start Button, Foot Actuator or at the Control | Collet system is air actuated with auxiliary start button - within easy reach of operator. Improves efficiency and safety for the operator. |

| Tool Box and Tools | A set of the basic tools required for maintenance are included with this late. Gives you what you need to get up and running and for routine maintenance. |

| Foundation Pads | Heavy machined leveling pads that adjust the height to keep your machine aligned and balanced. Solid multi-point contact with shop floor reduces vibrations and increases accuracy. |

| Drive System | |

| 4 HP Spindle Drive | Plenty of power to match the machine’s capacity. Capable of rigid tapping and spindle positioning. |

| 50-3000 Spindle Speed Range | Infinitely variable speed ranges, from 50 to 3000 RPMs. No need for changing gears or belts. |

| Schneider Electrical Components | One reason we can offer an 18 month machine warranty is because of the recognized quality, and reliabilty of Schneider Electrical components. Highest reliability rating - highy efficient design reduces power usage. |

| High Quality Hiwin Linear Guideways w/Telescoping Covers | World-class standard linear motion guideways come standard on the FL300. Stainless steel telescoping guards provide maximum protection of guideways from chips and coolant. |

| PMI Ball Screws | PMI ball screws efficiently transmit rotary motion to linear motion - allowing for high speed, and highly accurate axis movements. Accurate ball circle diameters throughout the length of ball screw assures consistent drag torque and low noise. |

| Feed Rates of 600 on X and Y Axes | Faster speeds equals higher production rates. The combination of Siemens industrial control, servo driven system and linear guideways provides power and control that allows for higher speeds on this machine - many times faster then competitive CNC Lathe systems. |

| Safety/Operation | |

| Ergonomic Control Panel and Operator Interface | Machine control panel adjusts and rotates up to 90 degrees. High tactile buttons, manual pulse generator, and convenient cycle start buttons improve operator convenience, efficiency, and safety. |

| Auxiliary Cycle Start | Easy access buttons allow operator to operate pneumatic or hydraulic chuck with the push of a button. Having a second E-Stop within easy reach also adds to the safety features of this lathe. |

| Manual Pulse Generator | Handheld pendant that allows operator to be independent from the main control panel. The rotating knob generates pulses that are sent to the machine control, allowing the operator to move the lathe a predetermined distance with each click of the knob detent. |

| Automatic Lubrication System | Lubricates all wear points during machine operation at continuous time intervals. Benefits include reduced labor and material costs, and significant extension of bearing life. |

| Programmable Coolant System | Control coolant flow at the control panel using standard M-Codes. Cycle times can be significantly reduced, while feed and cutting speeds can be significantly increased. Proper cooling extends life of cutting tools. |

| Work Light | Focused lighting elements increase operator efficiency and reduce fatigue. This light is flicker resistant - also waterproof, resistant to cooling and lubricants. Impact and vibration resistant. |

| Tri-Color Alarm Light | Green light turns red when control alarm recognizes a machining error, or machine malfunction. An operator standing away from the machine is visually alerted by the activated alarm light when machining cycle is finished or machine errors out. |

| Siemens 808D CNC Control | |

| Closed Loop System | System directly monitors motor position and velocity in real time. The system then automatically makes corrections to assure correct tool positioning. High accuracy and maximum parts quality ensures a minimal rejection rate. Also assures smoother surface finishes. |

| Siemens Servos and Drives | Achieves rapid acceleration and higher speeds - maintains high torque throughout speed range. Motor is highly efficient - and it stays cool. Quiet at high speeds, with vibration free operation. |

| Ideal for CNC Beginners | Ideal for entry level CNC users, the innovative, integrative start-GUIDE from Siemens provides an on-line digital help function on every screen. Helpful instructions are available anytime - at a push of a button. |

| Simple & Intuitive Interface | Well designed conversational programming functions and Wizards from Siemens help streamline programming at the control panel. All Siemens 808D controls come standard with this SINUMERIK Operate BASIC functionality. |

| Compact and Robust | Industrial panel design with hardened features is ideal for harsh environments. Small compact design matches smaller machines tools like the AutoMate CNC line. |

| USB Connector - Easily Handles Large Files | This unique Siemens function allows for the streaming of large program files direct from a USB. Large files are no longer a concern - other CNC systems lack this robust level of functionality. |

| Built-In Helps | Several Siemens provided “assists” help streamline programming functions. One example would be Hot Keys. With the Hot Key function, machine operators can easily access commonly used screens using operator defined hot keys. |

SPECIFICATIONS

| GENERAL SPECIFICATIONS - AUTOMATE CNC GANG TOOL LATHES | ||||

| Photo |

|

|

||

| Model Name | FL300 Flat Bed Gang Tool Lathe | SL280 Slant Bed Gang Tool Late | ||

| Price | $19,999 | $21,899 | ||

| TURNING CAPACITIES | ||||

| Max Swing Over Bed | 17.5” | 16.5” | ||

| Max Swing Over Carriage | 5.25” | 5.5” | ||

| Machine Repeatability | .0002” | .0002” | ||

| TRAVELS & FEED RATES | ||||

| X Axis | 14” | 11” | ||

| Z Axis | 12” | 13” | ||

| X-Axis Rapids | 950 IPM | 1100 IPM | ||

| Z-Axis Rapids | 950 IPM | 1100 IPM | ||

| Max Cutting Speed | 315 IPM | 315 IPM | ||

| SPINDLE | ||||

| Spindle Power | 4 HP | 5 HP | ||

| RPM Range | 50-3000 | 50-3000 | ||

| Spindle Bore | 1.46” | 1.89” | ||

| Spindle Nose Taper | A2-4 | A2-5 | ||

| Chuck Type | Pneumatic Chuck | Pneumatic Chuck | ||

| WEIGHT/DIMENSIONS/CAPACITIES | ||||

| Machine Weight | 3960 lbs | 4400 lbs | ||

| Machine Dimensions | 80” x 58” x 67.5” | 79” x 60” x 65.5” | ||

| Shipping Weight | 4260 lbs | 5070 lbs | ||

| Air for Pneumatics | 90 PSI | 90 PSI | ||

| Coolant Capacity | 11 Gal | 15.3 Gal | ||

| Hydraulic Capacity | 11 Gal | 13.2 Gal | ||

| Power (Standard) | 220V 3 Phase Power | 220V 3 Phase Power | ||

| Amperage Requirements | 20 Amp | 20 Amp | ||